What is a Pill Press: A Detailed Overview

What is a pill press? A pharmaceutical machine smashes powder into solid pills, ejects the pills as well, and collects them. As with any other large machine, the pill press is more than meets the eye.

Definition of tablet press machine

A pill press, also named a tablet press, is a mechanical device made to squeeze powder material into tablets. It can be used to produce candies, mooncakes, as well as pharmaceutical pills.

Through other names of it— tablet compression machine or tablet punching machine, it’s obvious this machine does compress or punch powder into tablets.

To meet the demand for mass production of pills or other particular goods, a pill press often has one or several dies to transfer the powder and tablets. Therefore, its final definition would be “an electrical machine being used to compress the powder into designed-shaped pills and transfer the pills to the next stage”.

Types of tableting machines

What is a pill press? According to the features of tableting machines, there are several categories.

Single-punch tablet presses, flower-basket tablet presses, and rotary tablet presses are three common types of tableting machines. Here are some details of them.

1) Single-punch tablet press

Single-punch tablet presses are commonly used to make a small number of tablets. Laboratories hold most of them to make various kinds of pills, including calcium pills, sugar tablets, and pharmaceutical pills. In other words, they are medical investigators’ favorite.

For most users, single-punch tablet presses have many benefits. They are simple to use, easy to carry, and can meet most demands of daily use. Their power can be electricity. Some of these presses also support manual operation. That would require the user to shake the handle.

After being fixed on the operation desk, users just need to plug in when they are put into use. Although a frequent check is needed, the machine won’t have many problems if the oil process is proper during the changing shifts.

However, this press can only use one die at a time. When users need to make several differently shaped pills, obviously,y it’s not a good option to choose a single-punch tablet press. Besides, the pill press would brush away the sprayed powder, so it would be a huge waste of raw materials when facing mass production.

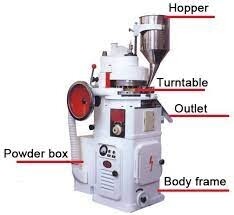

2) Rotary tablet press

Differing from the speed of rotation, the automatic degree, or the products, rotary tablet presses are categorized into sub-high-speed rotary tablet presses, fully automatic high-speed tablet presses, and rotary core-spun tablet presses.

These pill presses are quite different from the single-punch ones, for they are larger and faster in compressing and transferring pills. The complex structures make it possible to move smoothly and stably, and the pressure adjustment is synchronous.

Most pharmaceutical factories use rotary tablet presses in their production. Compared to single-punch ones, rotary tablet presses are more efficient in manufacturing.

The machine is equipped with a powder suction box. The dust generated will be absorbed by the suction nozzle to avoid sticking and blockage, so that the raw materials can be recycled for reuse. That means a lot to the mass production of pills.

iPharMachine has a series of rotary tableting machines. Not only do they produce tablets with super efficiency, but the AI system also helps make sure the machines function accurately.

Parts of tablet machines

We can divide the tablet machine into three parts: transmission part, pressurizing part, and weighing part.

The transmission part contains two small parts. The feeder ejects preprocessed granular material into the dies, and the tail over the die limits the amount of mixture in every die. Then the dies will carry it to the last station.

The pressurizing part is the most essential one among the three parts. Pressure mechanisms, aka punches, are symmetrical in the machine. The upper punches are forced to squeeze the lower punches by two sets of rolls—the pre-compression rolls and the main compression rolls. Together with four sets of cams, the punches move up and down, compressing and ejecting the pills.

The weighing part contains two sections. The weight adjustment ramp helps the dies to hold enough granular material inside, and the weight control unit helps to keep the weight in each die the same.

Working principle of tablet press machines

Maybe some readers think the working principle of tablet press machines is just compressing powder into tablets. It’s not exactly right. The powder of raw material would harm the tablet press.

The first step is to preprocess the raw material. As we could imagine, the powder remains powder after the compression, so we need excipients to help active ingredients become small granules. This process is granulation.

This would happen inside a fluid bed granulator or mixer, which varies from material to material. After thorough mixing, the powder would become granules big enough to hold each other together after compression.

After granulation, the granules are not yet ready for compression. In the last step, we put all the ingredients inside some kind of liquid. To remove the impurities, the next step is to put the mixture into a drying machine.

The purified mixture then goes into the pill press. The fill cam allows the lower punch to move down to make room for the mixture. The feeder pours the mixture into the dies, often the machine will blend the mixture to make sure it’s perfectly mixed. The weight control unit keeps all the mixtures in different die cavitiesat the same weight.

As the dies move further, the pre-compression rolls force the upper punches to give a little pressure to the mixed material. The main compression rolls then compress the mixture into pills. The two-step compression aims to make the tablets compress evenly.

The upper lifting cam then drives the upper punches up. At the same time, the ejection cam pushes the compressed tablets out to the surface of the dies. The scrapper would collect the pills, and the whole process is done.

Conclusion

These are just some features and functions of pill presses. As science develops rapidly, a growing share of advanced pill presses will come out. The revolution of the tablet press will continue, just as the bright future of the pharmaceutical industry.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche