Top 5 Best Capsule Filling Machines in 2024

If you're thinking about scaling up your pharmaceutical or nutraceutical business quickly, investing in an automatic capsule filling machine would be a smart move. Yet, for the uninitiated, finding the best automatic capsule filler can be challenging. But don't worry, we're here to help. This article will give you the lowdown on what you need to know when picking out the best automatic capsule filling machine. And feel free to check another post, if you want to learn the key features of the best manual capsule filler.

Before we get to the point, let's take a look at the types of capsule fillers. Fully automatic capsule filling machines are the third type of capsule filler available on the market, in addition to manual and semi-auto models.

You are certainly no stranger to the latter two. The fully automatic one is a machine suitable for large-scale commercial manufacturing. It's specifically designed to fill powder, pellets, granules, micro-tablets, liquids, and combinations into hard-shell capsules in an automated fashion.

At iPharMachine, we strive to offer the highest-quality capsule filling machines to pharmaceutical and nutraceutical companies across the globe. Below, we'll walk you through some of our state-of-the-art products that may be just what you're looking for:

1. RN-100CL

The RN-100CL is a cutting-edge addition to iPharMachine's line of manual capsule filling machines. This gadget comes in a unique circular shape, making it stand out from the pack. This hand-operated device takes the best features of both square and rectangle ones.

The RN-100CL is designed to fill separated capsules. It’s simple to operate and does a great job of reducing powder waste. Its well-designed capsule plates can quickly and accurately align capsule caps and bodies for powder packing. These transparent, glossy capsule plates are crafted from imported PMMA. The substance is thick and flexible. And even after prolonged use, it shows no signs of deformation, cracking, or yellowing.

The RN-100CL can double or triple the production of square manual capsule fillers. Compared to using traditional capsule filling plates, the output can be increased by 4-10 times. This manual capsule filling machine is ideal for laboratories, clinics, homes, and other low-volume operations.

Features:

- Made of PMMA material and stainless steel for a longer lifespan

- Unique tamper with SUS304 cylindrical pins

- Round spill guard for reducing powder waste

- Simple and speedy disassembly and cleaning design

- Capable of handling capsule sizes from 000 to 5

- 99.9% success rate for capsule closing

- Enhanced filling accuracy, efficiency, and consistency

- 2-3 times more productive than square and rectangular manual capsule fillers

- 4-10 times more productive than conventional capsule filling plates

Technical data:

|

Capsule size |

#000 |

#00 |

#0 |

#1 |

#2 |

#3 |

#4 |

#5 |

|

Number of holes |

100 |

|||||||

|

Material |

PMMA |

|||||||

|

Upside-down |

0.3% |

|||||||

|

Scrap rate |

0.1% |

|||||||

|

Output |

2400 pcs |

|||||||

|

Closing pressure |

200 N / 50 pcs |

|||||||

|

Dimensions (mm) |

Φ198*86 |

Φ198*80 |

Φ198*80 |

Φ198*76 |

Φ198*74 |

Φ198*74 |

Φ198*68 |

Φ198*62 |

|

Weight (kg) |

2.38 |

2.08 |

1.78 |

1.69 |

1.67 |

1.51 |

1.52 |

1.33 |

|

|

||||||||

|

Part name |

304 SS |

PMMA |

PE |

|

|

|||

|

Alignment plate |

Screw |

√ |

|

|

|

|||

|

Cap plate |

|

√ |

|

|

|

|||

|

Body plate |

Screw, nut, spring |

√ |

|

|

|

|||

|

Spill guard |

|

√ |

|

|

|

|||

|

Tamper |

√ |

√ |

|

|

|

|||

|

Spatula |

|

|

√ |

|

|

|||

|

Middle plate |

Screw |

√ |

|

|

|

|||

2. CN-100M

The CN-100M is an upgraded hand-operated capsule filling machine available at iPharMachine. This model comes in a regular square shape. Unlike its siblings, the capsule filling machine is designed to handle joined capsules.

Compared to pre-separated capsules, joined capsules can be stored in a safer way, no matter the temperature and humidity changes. The separation of empty capsules is done by the machine itself. This minimizes the risk of contamination that may occur in separated capsules.

Further, all machine components are made of 304 stainless steel, PMMA, PE, anodized aluminum, and PC, following Good Manufacturing Practice (GMP) regulations. The success rate of filling and closing capsules is 99.9%, even for deformed capsules.

If you’re running a small-scale business but looking to quickly improve the filling accuracy and efficiency, the CN-100M will be a solid choice.

Features:

- 10x increase in production output compared to fully manual operations

- Avoid direct contact with capsules and powders

- Effectively solve the fill variation problem

- Capable of handling capsule sizes from 00 to 5

- 99.9% success rate for capsule filling and closing

- Integrated spill guard for minimizing powder waste

- Suitable for separation and closing of mechanically sealed capsules

- Instant and automatic adjustment of capsule direction

- Unique anodized material for strict hygiene and safety compliance

Technical data:

|

Capsule size |

#00 |

#0 |

#1 |

#2 |

#3 |

#4 |

#5 |

|

|

Number of holes |

100 |

|||||||

|

Material |

Stainless Steel |

|||||||

|

Upside-down |

0.2% |

|||||||

|

Scrap rate |

0.1% |

|||||||

|

Output |

2000 pcs |

|||||||

|

Closing pressure |

200 N / 50 pcs |

|||||||

|

Dimensions (mm) |

236*230*157 |

236*230*126 |

236*230*119 |

236*230*119 |

236*230*117 |

236*230*115 |

236*230*115 |

|

|

Weight (kg) |

5.48 |

4.83 |

4.81 |

4.64 |

4.62 |

4.79 |

4.92 |

|

|

|

||||||||

|

Part name |

304 SS |

PMMA |

PE |

Anodized Al |

PC |

|

|

|

|

Alignment plate |

√ |

√ |

|

|

√ |

|

|

|

|

Middle plate |

√ |

|

|

√ |

|

|

|

|

|

Body plate |

√ |

|

|

|

|

|

|

|

|

Spill guard |

|

√ |

|

|

|

|

|

|

|

Tamper |

√ |

√ |

|

|

|

|

|

|

|

Spatula |

|

|

√ |

|

|

|

|

|

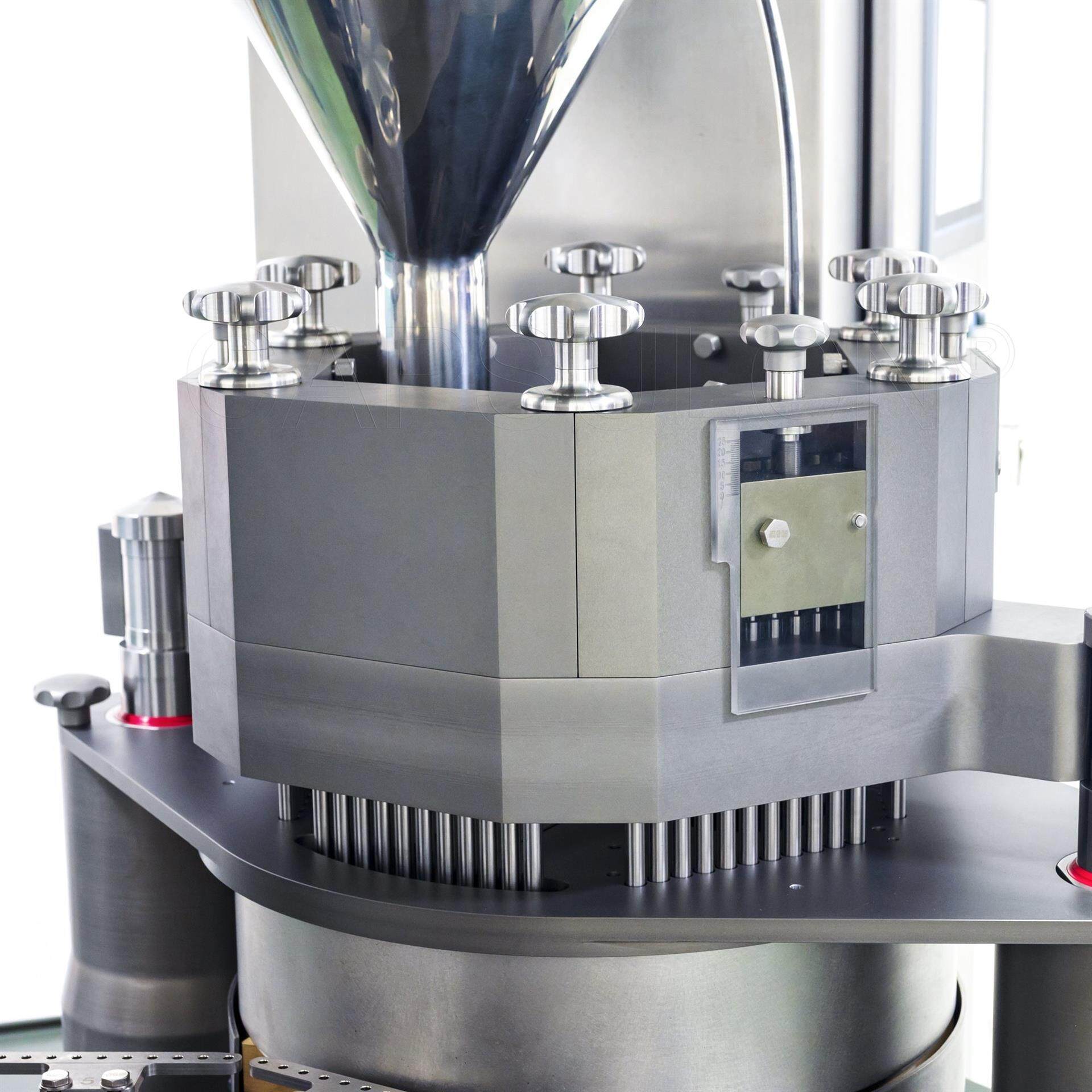

3. JTJ-V Pro+

The JTJ-V Pro+ Semi-Automatic Capsule Filling Machine is one of the flagship products at iPharMachine. As the most advanced model from the JTJ-V series, this piece of equipment features an innovative and flexible design.

The JTJ-V Pro+ boasts a dual loading system, enabling it to be on a par with our NJP-800 fully automatic capsule filling machine in terms of output capacity. This semi-automatic capsule filler is packed with the superior craftsmanship and high efficiency of the JTJ-V series.

Features:

- 10,000-hour failure-free operation

- Double loading system, enhanced output capacity

- Variable speed control, independent motor

- Horizontal closing system with higher efficiency and capsule protection

- Flexible discharge chute

- Hard anodized filling rings for longer service life

- Filling ring holders

- Hard anodized tabletop with rounded corners for operation safety

- PLC with touchscreen

- Swivel casters for easy movement

- Organized electrical enclosures

- cGMP-compliant design

Technical data:

|

Output |

30,000-50,000 caps/h |

|

Capsule sizes |

#000-#3, safety capsules |

|

Oral dosage forms |

Powder, granules, pellets, micro-tablets |

|

Vacuum pump |

40m3/h |

|

Compressed air |

0.03m3/min, 0.7MPa |

|

Dimensions |

1140 x 700 x 1630 mm |

|

Net weight |

380 kg |

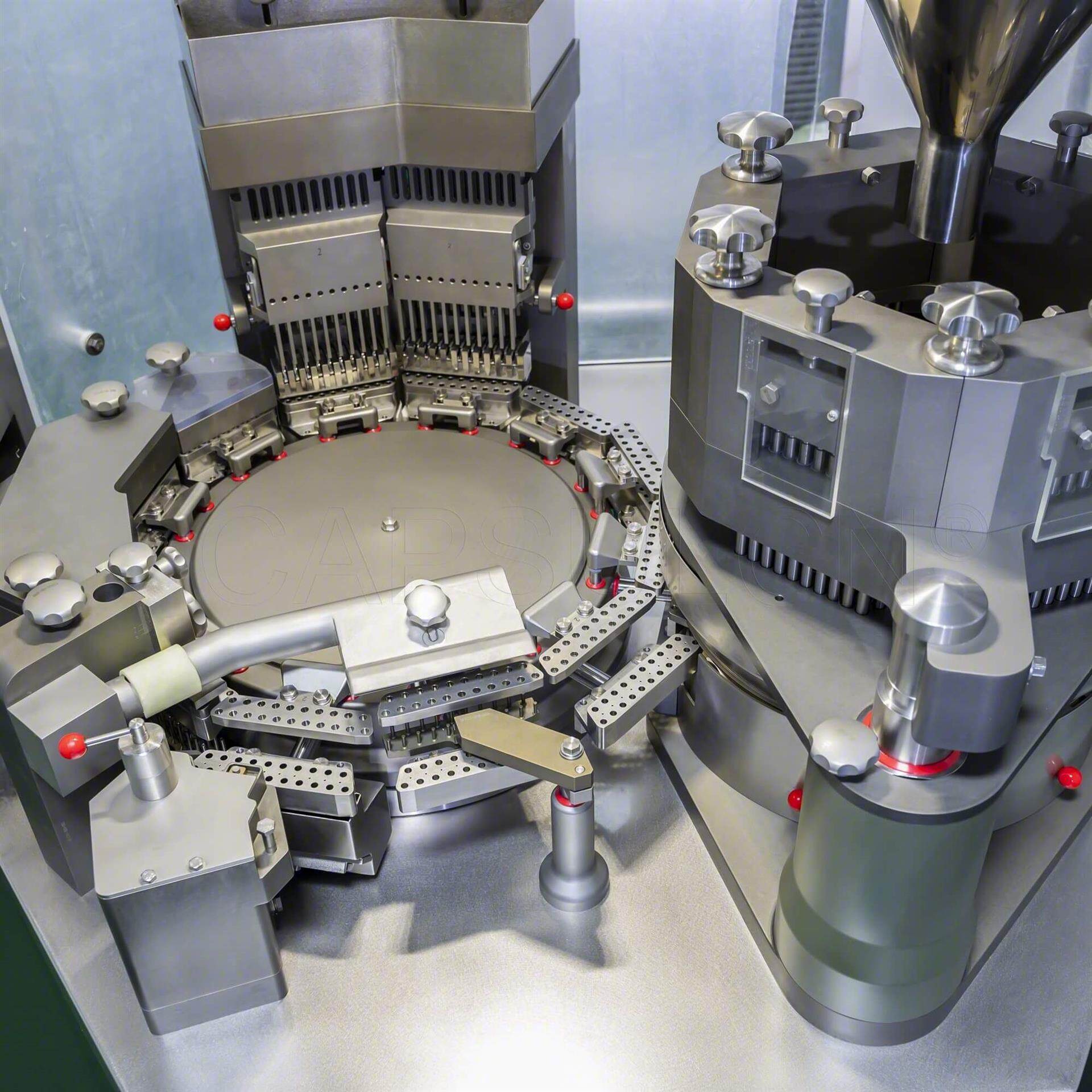

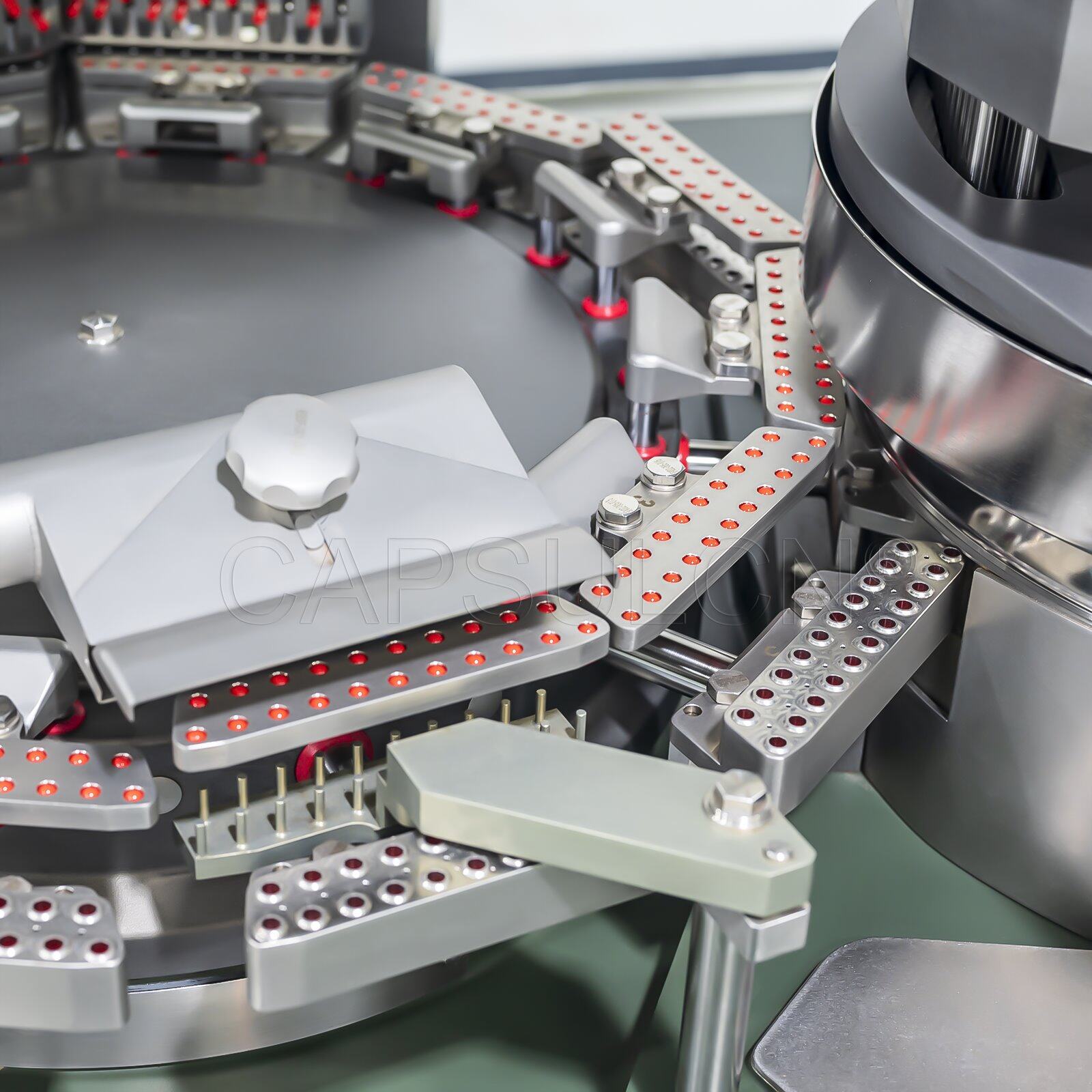

4. NJP-1200C

The NJP-1200C Automatic Capsule Filling Machine is the iconic iPharMachine product, as well as one of our best-selling automatic capsule filling machines. Thanks to fine craftsmanship and high performance, this product has received a lot of positive reviews from customers around the world.

cGMP-compliant and CE-marked, the NJP-1200C comes in a 304 stainless steel construction with a small footprint. It's designed for filling powder, granules, micro-tablets, and pellets into hard-shell capsules. Empowered by multiple patented technologies, this machine provides you with robust design, high filling accuracy, outstanding production flexibility, and long service life.

Features:

- PLC control system, digital display

- Improved turntable, built with made-in-Japan linear bearings for longer service life and enhanced filling precision

- Continuous monitoring for real-time alarms and alerts

- Multiple mechanisms with patented technologies

- Built-in reject system and industrial vacuum cleaner

- Simple to use, low-maintenance, easy-changeover

- Equipped with interlocking guards for operator safety

Technical data:

|

Output |

72,000 caps/h |

|

Segment bores |

9 |

|

Capsule sizes |

#00-#5, safety capsules |

|

Oral dosage forms |

Powder, granules, pellets, micro-tablets |

|

Power supply |

380/220V, 50/60Hz, 6kW |

|

Noise level |

<75dB |

|

Dimensions |

1180 x 1340 x 1980 mm |

|

Net weight |

1000 kg |

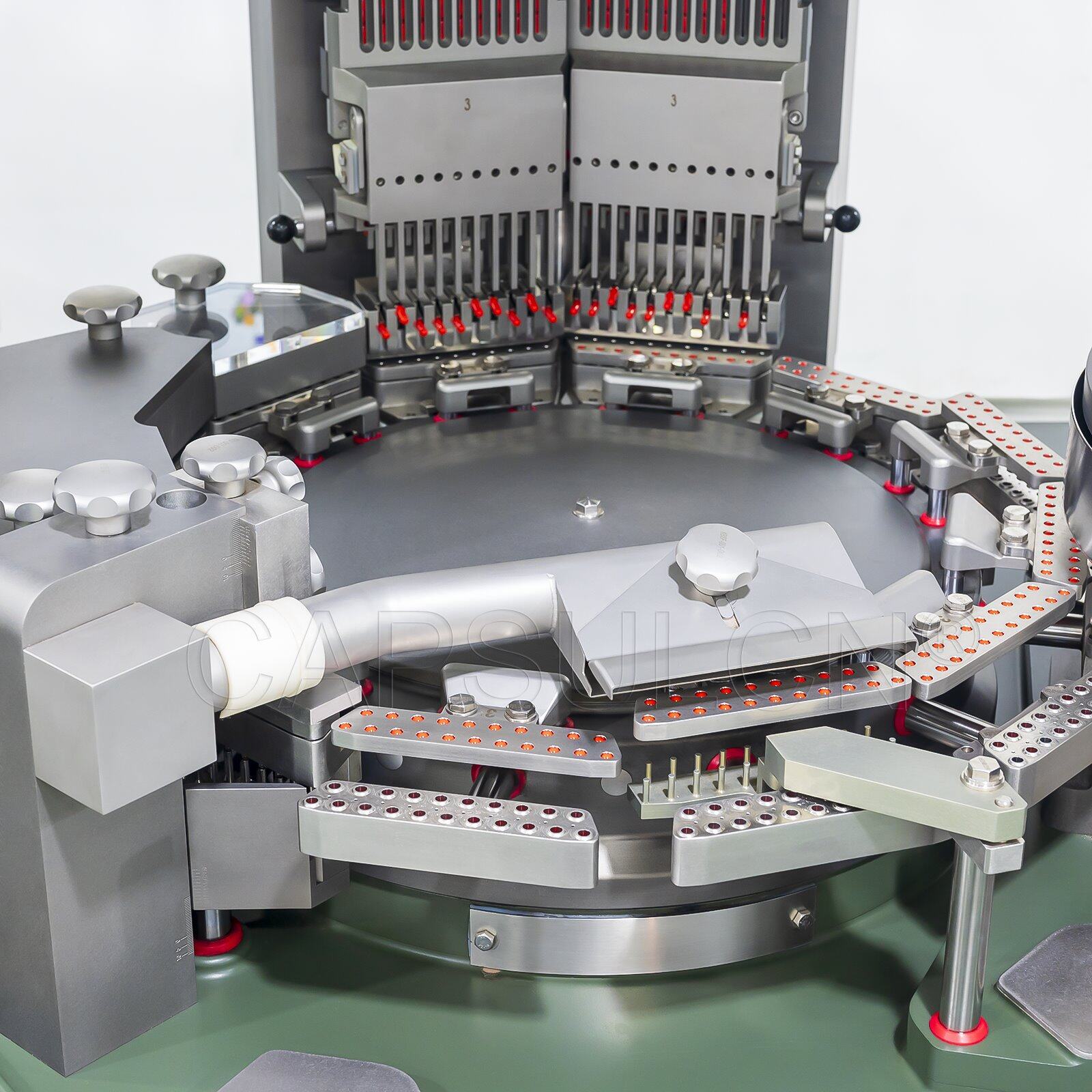

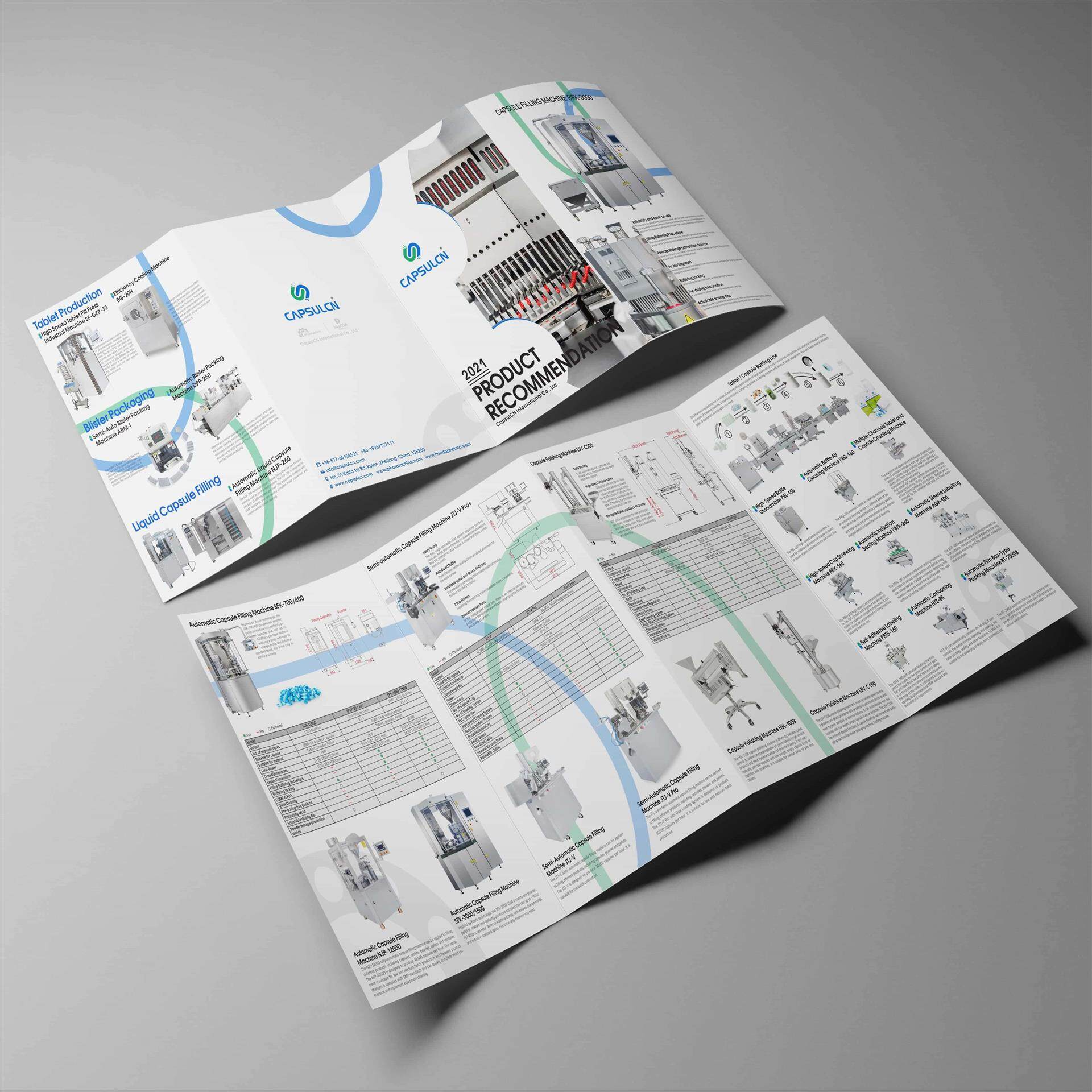

5. SFK-700

The SFK-700 is the most popular model from our state-of-the-art SFK Series Automatic Capsule Filling Machines. The production capacity of this machine can meet the needs of small or medium-sized to large pharma and supplement companies.

Both superior craftsmanship and exceptional performance enable the SFK-700 to rival the most advanced automatic capsule filling machines in the global market. This future-proof machine features a modular construction that allows for handling a wide range of formulations, including powder, pellets, micro-tablets, and more.

Features:

- Robust, flexible modular design

- SIMATIC control system and HMI touchscreen, NORD motor, SANKYO gearbox

- High-quality electrical components for enhanced durability and stability

- Continuous cam control, use FCD700 camshaft

- Well-manufactured stainless steel parts without burrs and sharp edges

- Low noise, easy integration, easy to clean, low maintenance, quick changeover

- Built with interlocking guards for operator safety

- Small footprint, low energy consumption

Technical data:

|

Output |

42,000 caps/h |

|

Segment bores |

5 |

|

Capsule sizes |

#00-#5 |

|

Oral dosage forms |

Powder, granules, pellets, micro-tablets |

|

Power supply |

380/220V, 50/60Hz, 3kW |

|

Noise level |

<70dB |

|

Dimensions |

951 x 1551 x 2155 mm |

|

Net weight |

2500 kg |

What are the features and benefits of the best capsule filling machine?

There's no doubt that you can get more out of an automatic capsule filling machine compared to using the manual and semi-auto types. The point is you need to use the best equipment.

Here are the five most common benefits of integrating the best capsule filling machine into your capsule filling line.

1. Higher production speed

First and foremost, the best capsule filling machine is typically PLC-powered and equipped with variable frequency drives (VFDs). These VFDs provide precise variable speed control functions, enabling the capsule filler to manufacture more than those that could be produced by any hand-operated or semi-auto machines.

Today, automatic capsule filling machines can give an output ranging from 24,000 to 450,000 caps per hour depending on the formulations, having all your production needs covered.

2. Consistency and reliability

The best automatic capsule filling machine can ensure higher accuracy and precision than a hand-operated or semi-auto capsule filling process.

When filling capsules with poorly-flowing powders, achieving the fill weight uniformity can be tricky. The best capsule filling machine is now equipped with a vacuum loading system on the powder hopper. This system allows dosing at uniform fill weights using a vacuum, ensuring a smooth material flow at a high encapsulation speed.

In addition, the best automatic capsule-filling machine consists of a range of high-performance parts, such as a dosing disc. The dosing disc is customizable and comes in many different types to fit a variety of applications. The dosing disc can precisely control the fill weights, ensuring a reliable and consistent production run.

3. Versatility and flexibility

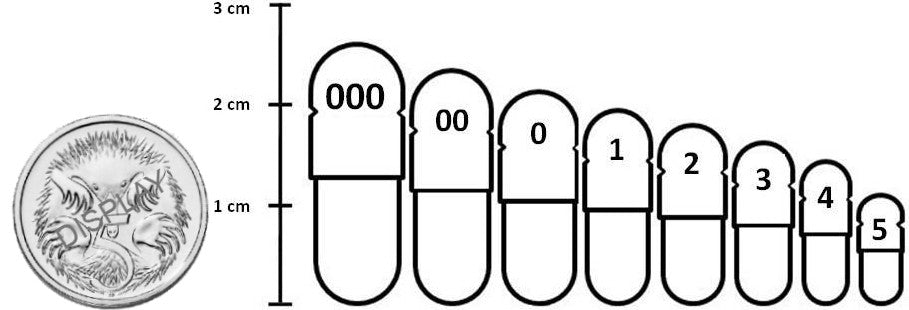

Automatic capsule filling machines are not always built for one single product. The best capsule filling machine is capable of handling the full range of capsule sizes from #000 to #5. In addition, the best model is designed for handling multiple formulations, including powders, pellets, granules, micro-tablets, liquids, and combinations. If your company plans to fill multiple products, a versatile capsule filling machine will be your best bet.

(Image Source: Empty Capsules)

Further, flexibility is certainly another feature of automatic capsule filling machines. The best capsule filling machine can work in synergy with other support equipment, allowing your production line to run more smoothly and efficiently.

4. Simple operation and low maintenance

Automation endows the best capsule filling machine with the features of simple operation. The capsule filler provides a range of continuous processes, minimizing human intervention. All settings, such as feeding, separating, filling, closing, discharging, and more, will be set on an HMI touchscreen, enabling you to easily control all machine's attributes.

Also, the best capsule filling machine is well designed for easy assembly and disassembly, allowing quick tooling changeover and easy maintenance.

5. Scalability

Finally, your business can expand with the help of capsule fillers. The design of the best automatic capsule filling machine allows for more filling stations to be integrated in parallel and speed upgrades, providing scalability to keep up with the pace of your production and demand increase.

How to choose the best capsule filling machine: 6 things to consider

Finding the best capsule filling machine for your business can be challenging since there are so many products available on the market today. When you're looking for a capsule filler that suits you best, here are 6 things you need to keep in mind.

1. Size of the machine

This is one of the most crucial factors you should consider. The machine's size is related to its power efficiency and production capacity. Though automatic capsule filling machines are suitable for large-scale production, it still depends on your business's unique needs.

To determine the size of your machine, you should do your own math first. Do you have enough shop floor space to accommodate a new, large unit? How many capsules do you want to produce per day? How many capsules can you sell per month or year under normal conditions? With these questions in mind, you can pick out what kind of machine you'll need.

2. Capsule Size:

If you're engaged in manufacturing dietary supplements, capsule sizes #00 and #0 are the most popular options because they are easier to swallow. Yet, the capsule size varies from product to product based on the density or mass of your formulations. It means "Fill Material A" and "Fill Material B" may not fit the same capsule size even though they weigh the same. So, choose the capsule filler that can handle the capsule size right for your formula.

Capsule filling machines come in different sizes to accommodate different types of capsules. It's essential to consider the size and type of capsule you will be using to ensure that the machine can handle it. Some machines are designed for specific capsule sizes and types, while others can handle multiple sizes.

Here's a chart of some common capsule sizes and their dimensions:

|

Capsule Size |

Volume |

Length |

Diameter |

|

000 |

1.37 ml |

26.2 mm |

10.7 mm |

|

00 |

0.95 ml |

23.4 mm |

9.9 mm |

|

0E |

0.68 ml |

21.2 mm |

8.2 mm |

|

0 |

0.68 ml |

21.2 mm |

7.6 mm |

|

1 |

0.50 ml |

19.4 mm |

6.9 mm |

|

2 |

0.37 ml |

18.4 mm |

6.4 mm |

|

3 |

0.30 ml |

16.0 mm |

5.8 mm |

|

4 |

0.21 ml |

14.8 mm |

5.3 mm |

|

5 |

0.13 ml |

11.7 mm |

4.9 mm |

Note that these sizes are just a guide and can vary slightly between manufacturers. Additionally, some manufacturers may offer additional sizes not listed here. It's important to select the right size for your application, and the specific capsule filling machine you choose will need to be compatible with the size of capsules you intend to use.

3. Capsule Types:

There are two main types of capsules used in the pharmaceutical and supplement industries: gelatin capsules and vegetarian capsules. Here's a brief introduction to each type:

-

Gelatin capsules:

Gelatin capsules are made from a mixture of gelatin, water, and a plasticizer such as glycerin. Gelatin capsules are widely used in the pharmaceutical industry because they are relatively inexpensive to produce, easy to swallow, and can be manufactured in a wide range of sizes and shapes. Gelatin capsules are also an effective way to mask unpleasant tastes or odors.

-

Vegetarian capsules:

Vegetarian capsules are made from plant cellulose or other non-animal materials, such as pullulan. These capsules are becoming increasingly popular, especially among consumers who prefer to avoid animal products. Vegetarian capsules are also an effective alternative for people with dietary restrictions or allergies. While they are generally more expensive than gelatin capsules, they are still widely used in the supplement industry.

Both gelatin and vegetarian capsules can be produced in a variety of sizes, colors, and shapes, and can be filled with a wide range of materials, such as powders, liquids, or pellets. The type of capsule you choose will depend on your specific needs, preferences, and regulatory requirements.

3. Product quality

Most people would agree that product quality is important, but not everyone agrees on what high quality is. For instance, some people value luxury and durability, while others may value efficiency or easy operation more.

The quality of an automatic filling machine is determined by how well it lives up to user expectations. It can be measured by market price and consumer satisfaction. The best capsule filling machine will function way better and last longer than its competitors, even if it carries a higher price tag.

The most immediate way to judge the quality of a capsule filling machine is to go through customer reviews. The feedback will help you know what other customers think about the machine.

4. Features

Features are an element of the best automatic filling machine to make it stand out from its rivals. The equipment's features are typically available on the manufacturer's website or its marketing materials, allowing you to get a rough idea of the machine before buying.

If you're looking for the right capsule filler, you should figure out if it has the features you need. If so, then go ahead and take the next step. Features matter because they can increase customer satisfaction by offering benefits that people value.

5. Value for money

Automatic capsule fillers always have a hefty price tag, so you should ensure that your purchase is worth the cost. The best capsule filling machine not only delivers optimal performance but also offers the best value for money.

The best way to decide if the capsule filling machine is worth buying is to do your research. Compare its price and features with those of other similar machines. Find out if the equipment will serve you for a long time.

6. Customer service

Considerate customer service is an integral part of the best capsule filling machine. Modern machines are all complex systems that require professionals for maintenance or repair if necessary. When considering a purchase, you need to know whether the equipment manufacturer or supplier offers operator training, field service, and other technical support.

Your Reliable Partner

iPharmachine is a global leader in capsule filling and packaging solutions, serving the pharmaceutical, nutraceutical, and food industries. It offers a wide range of capsule filling machines, capsule polishing machines, and capsule counting machines, as well as a variety of empty capsules, including gelatin capsules, vegetarian capsules, and flavored capsules. The company's machines are designed to fill capsules with a variety of substances, including powders, granules, and pellets, and can accommodate different capsule sizes and shapes.

IPharmachine's capsule filling machines come in a variety of configurations to meet the specific needs of different pharmaceutical manufacturers. Some of the key features and capabilities of these machines include:

1. High accuracy:

IPharmachine's capsule filling machines are equipped with advanced dosing systems that ensure precise and consistent filling of capsules.

Flexibility: The machines can be configured to handle a wide range of capsule sizes and filling volumes, making them suitable for a variety of applications.

2. Speed:

IPharmachine's capsule filling machines are capable of high-speed filling, allowing for increased productivity and throughput.

3. Hygiene:

The machines are designed to meet the highest standards of hygiene, with easy-to-clean surfaces and components that can be quickly and easily disassembled for cleaning and sterilization.

4. Advanced controls:

IPharmachine's capsule filling machines are equipped with advanced control systems that allow for easy operation and monitoring of the filling process, as well as the ability to track and record production data for quality control purposes.

IPharmchine's capsule filling machines are reliable, efficient, and highly customizable solutions for pharmaceutical manufacturers looking to fill capsules with precision and consistency.

Final thoughts

If you've read this far, you must have a very clear idea of how to pick out the best automatic capsule filling machine. The right equipment will help improve the precision and productivity of your capsule manufacturing work. Also, your business can benefit from it in the long run.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche