Capsule Manufacturing Process: A Complete Guide

Capsules are the most vital elements of the pharmaceutical industry. Specific machines and processes are used to manufacture them. Every pharma company knows that capsule production takes a significant amount of time. The reason is the crucial steps that need to be followed.

We include everything in this article to help you with the effective capsule manufacturing process. Continue the reading and learn the complete process! And if you are individual users who are interested in producing capsules in small quantity, you may check this post "How to Make Your Own Capsules?"

What Is A Capsule Manufacturing Process?

The process of capsule manufacturing is essential for companies that deal with supplements and medicines. Usually, the process involves the steps that need to be followed for expected outcomes. It involves the whole parts, from melting the raw material to printing to shipping the packaged capsules.

Understanding the process will help your workers and company to manufacture the capsules successfully. So, let’s get into it and learn the overall steps in the following section!

Capsule Raw Materials & Manufacturing Environment

If you want to know how capsules are made, you must know about some basic requirements before starting manufacturing. Check some crucial things that will help you!

RAW MATERIAL

In the capsule manufacturing process, you should use high-quality raw materials—a few examples to meet the highest standards, including USP-NF, JP, and EP.

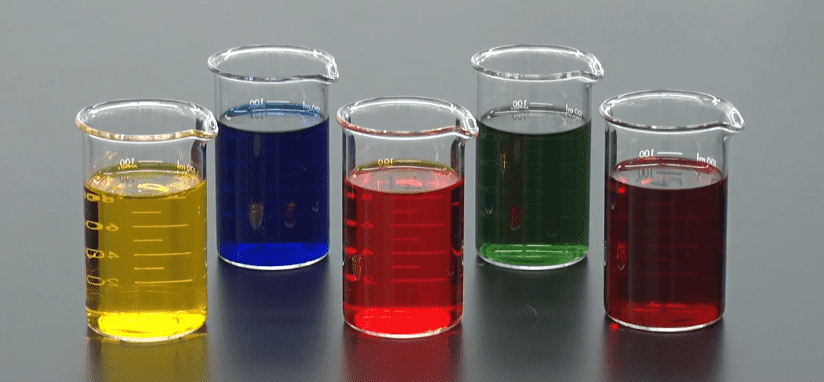

COLORANT

You can decide what type of capsule you want, colored or opaque. Colorants are generally used in the melting phase to give color to the pills.

CLEANLINESS

The most vital thing to do is the proper cleanliness of the manufacturing area. It is maintained to the ISO 14644-1 class 8 standard in pharmaceutical and medicine companies.

HYGIENE

The employees or workers involved in capsule production must strictly follow the hygiene guidelines. Before entering the manufacturing area, they must maintain hygiene from the beginning.

Capsule Manufacturing Process

The first part of the capsule manufacturing process involves melting the raw material. Moreover, the coloration is also done for easy distinguishability. Let’s check out the appropriate details and steps to make capsules:

PART 1: Raw Material Melting & Coloration

Step 1: The raw material that meets the acceptance test requirements is brought into the manufacturing area.

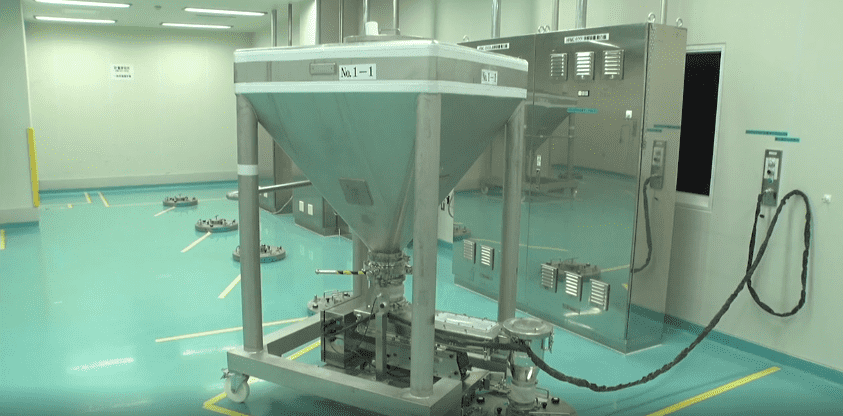

Step 2: Raw material contained in the hopper is automatically weighed in the container.

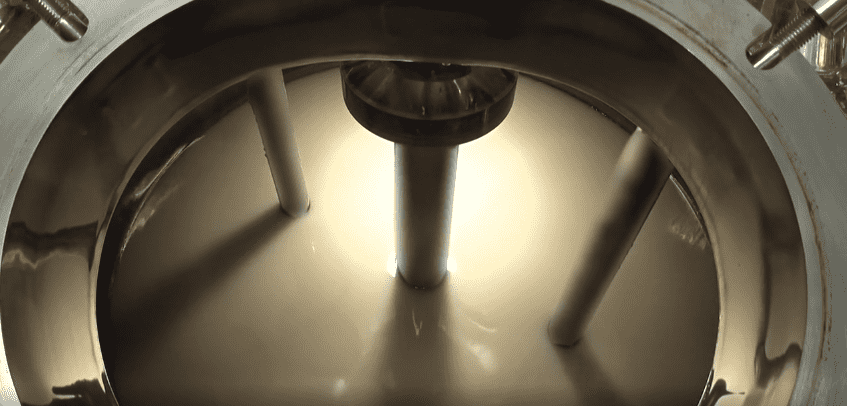

Step 3: Now, the weighted material will be shifted from the container to the melting tank.

Step 4: Purified water is added to the melting tank before finally starting the melting process.

Step 5: After initiating the melting, the mixture gets stirred to create a uniform jelly.

Step 6: In this step, the colorant can be added to the colored capsules.

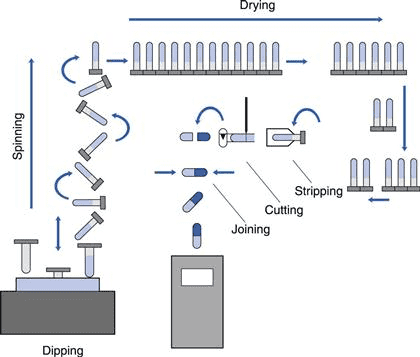

PART 2: Capsule Molding & Cutting

Step 1: In the capsule production room, the capsule manufacturing machines receive the colored jelly.

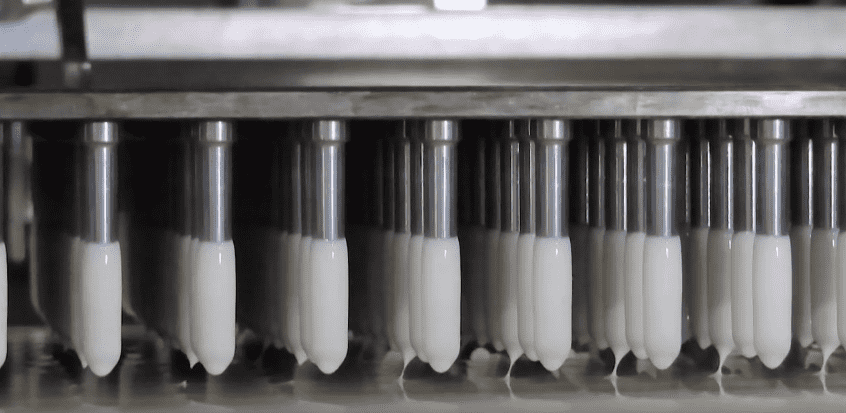

Step 2: The pins are then dipped into the jelly mixture. Molding pins are then shifted to the drying unit.

Step 3: The drying process will be at a constant temperature and humidity. After the drying process, these are sent to the next section.

Step 4: Now, the dried caps and bodies are removed from the molding pins.

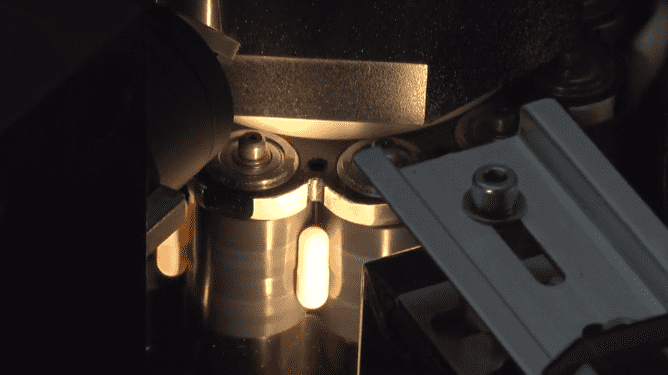

Step 5: The caps and bodies will be trimmed to an appropriate length and then pre-locked.

Step 6: Next, an immediate visual inspection of all the capsules will be done. The light is flashed on the rotating capsules, and the digital images are captured with cameras. Besides, image processing technology is used to detect abnormal shapes.

Step 7: In the last step, the conformed capsules will be packed into the containers.

PART 3: Printing, Inspection & Packaging

CAPSULE PRINTING

Step 1: Now, the printing of the capsules started for the product identification purpose.

Step 2: The specified design is printed in the capsules by utilizing the ink and printing machine of the company.

Step 3: An alternate option can also be used for printing without ink. In this part, you can use the laser printing machine.

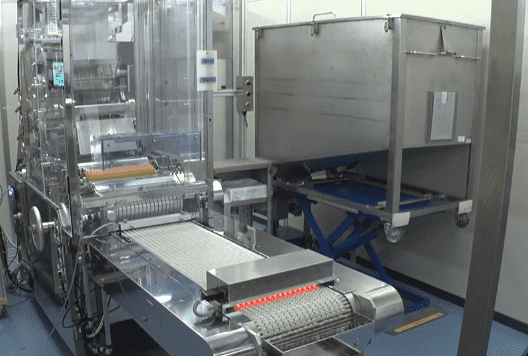

AUTOMATIC CAPSULE INSPECTION MACHINE

The automatic capsule inspection machine is designed to identify defects in capsules using advanced visual processing and automation technology. It has several features that make it ideal for use in industrial environments.

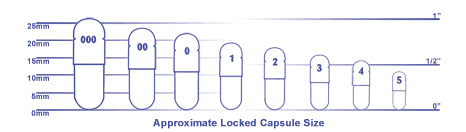

The operation of the machine is simple, and it is easy for staff to learn and operate. The machine can test specifications for 00#, 0#, 1#, 2#, 3#, and 4# capsules, and it can detect defects such as less filling, holes, internal chips, cracks, notches, short bodies, double hats, concave tops, thin spots, short and long hats, bubbles, black spots/heterochromatic spots, and others.

Step 1: Now, the capsules will be inspected using the capsule inspection machine.

Step 2: Counting of the capsules will be done.

Step 3: The conformed capsules will be shifted to the next container.

Step 4: Packaged capsules are stored in the product warehouse with controlled temperature and humidity.

PART 4: Shipping Tests & Shipment

The companies can do some tests before the shipment of the right capsule products. Capsules are generally tested for dimensions, appearance, moisture content, separation, and more. A few tests that you can perform on your manufactured capsules are:

- Visual Appearance Test

- Dimensional Test

- Microbial Test

- Separation Test

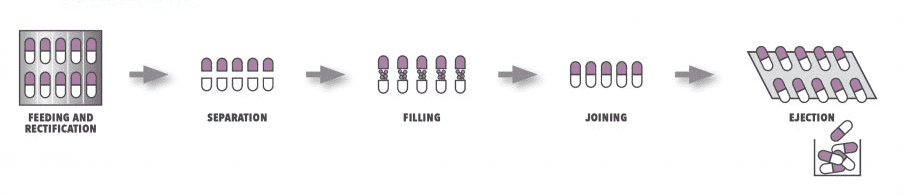

Capsules Filling Process

Now, let's check out the gelatin capsule filling process. Different capsule filling machines are available for the effective filling of the capsules. Below is a quick overview of how capsules can be filled:

SIMPLE STEPS FOR HARD GELATIN CAPSULE FILLING

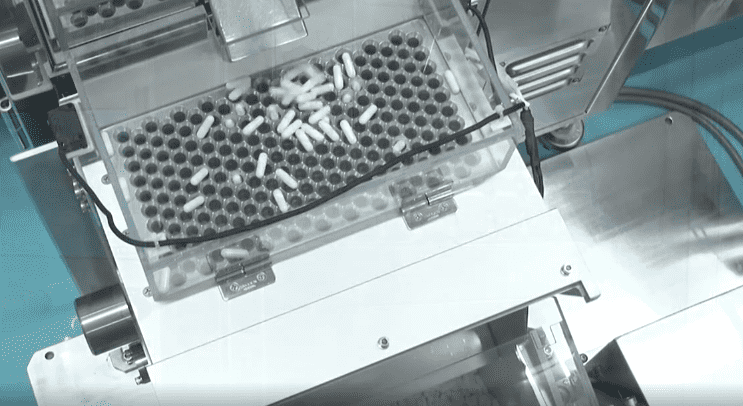

Step 1: First, take the removable plate and locate the empty gelatin capsules. You need to be sure about the downward-facing position.

Step 2: Separate the cap and bodies properly.

Step 3: Use a plastic spatula to fill the formulation into the capsule body. The excess powder has to be removed from the capsule.

Step 4: In the last step, close the filled capsule shells. Now, eject the capsule.

MANUAL POWDER FORMULATION FILLING

Manual powder filling to the hard gelatin capsules is vital for different purposes. Capsule manufacturing and research are some of them! If your want to know how gelatin capsules are made manually, the following steps can tell you how to do it:

Step 1: Place the powder to be filled on a porcelain plate or clean paper.

Step 2: Move ahead by pressing the capsule's open end in the downward direction.

Step 3: You should press until the capsule is filled.

Step 4: Lastly, use the cap on the capsule to close it.

Moreover, the manufacturing units with small-scale hand-operated capsule filling equipment provide about 200 to 2000 capsules every hour. While If you want to filling capsules in bulk, automatic capsule filling machines is your top choice. It is an intelligent device designed to fill capsules in bulk. It can produce up to 42,000 capsules per hour and is suitable for lhigh batch production with frequent product changes. The machine complies with GMP standards, allowing for quick mold conversion and easy equipment cleaning.

Some Capsule Manufacturing Defects

Defects are common in any manufacturing process. The following are some defects of the capsule manufacturing:

COLOR DEVIATION

The first defect that can occur in capsule manufacturing is color deviation. It means the color of the final capsule comes out differently than expected.

SHORT BODY/CAP

There is also a possibility of a defect during the cutting phase. The capsule may get trimmed shorter than the required size in this part.

LONG BODY/CAP

Like small size, there is also a chance that you may get a large size of the body or cap of the capsule.

DOUBLE CAP

The following capsule manufacturing defect is double cap capsules. In this kind of defect, the capsule body has two caps on it.

HOLES/SCRATCH

Holes and scratches are very common in the capsule production process. So, check for the capsule to see if it has any scratches or holes.

DAMAGED PRINT

Printing is vital for product identification. But sometimes, the capsule gets a damaged print, which is considered a manufacturing defect.

SPLIT

The splits can occur on the capsules due to uneven film thickness and inappropriate environmental conditions.

Frequently Asked Questions

How are medicine capsules made/filled?

Usually, the capsules are filled by admitting the powdered form into the capsule body from the hopper. It is done using the filling rings.

How are gelatin capsules made?

Gelatin capsules are basically soft and hard in nature. They are derived by the hydrolysis of collagen. It is done from a cellulose base or animal origin.

Why is gelatin used in capsules?

Gelatin is an excellent product for capsule manufacturing. It can protect the capsule contents from contamination, light, microbial growth, and other harmful factors. About 75% of the gelatin capsule market is the representation of hard capsules.

Why are the sizes for capsules?

Capsules have standard sizes, which are named after numerical values. The numbers are 000, 00, 0, 1, 2, 3, 4, and 5. All these numbers remain the same for all kinds of HPMC, Pullulan, and Gelatin. Most capsule manufacturing machines are designed to be compatible with these sizes.

In which type of capsule liquid is filled?

Liquid-filled hard capsules (LFHCs) are made of a gelatin or hydroxypropyl methylcellulose (HPMC) shell. These are filled with compatible liquids or compositions that can flow at temperatures below 70°C. LFHC technology has numerous advantages over other solid dosage forms.

End note On Capsule Manufacturing

Lastly, all the crucial aspects are available above if you want to polish your company’s capsule manufacturing process. You can see how every step makes an impact and how it affects production. Besides, cleanliness and hygiene maintenance are essential in the whole process.

If you want to buy an excellent capsule-filling machine, you can find it on iPharmachine. You can pick manual, semi-automatic, or fully automatic filling machines according to your requirements. After getting all the essential equipment, you can follow the effective capsule manufacturing process.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche