Coating Machine BYC-300: Working Principles

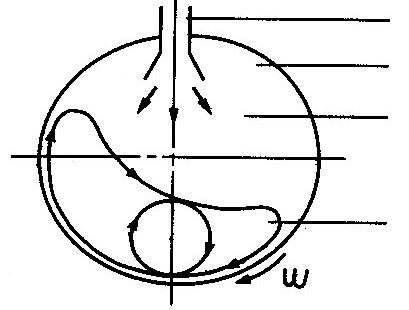

The pot body is at clockwise rotation and speed controlled by inverter. Spray gun sprays coating liquid is covered on the chips evenly. In the meantime, we can get standard coating tablets by connecting hot air to remove moisture of the surface.

This Coating Machine is reasonably controlled, stable linear speed and fastening baffler to enable tablets form the best logistic curve and meets the standard of film coating.

Logistics curve

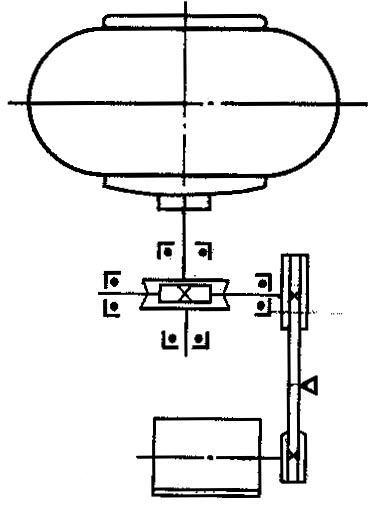

Transmission Principle

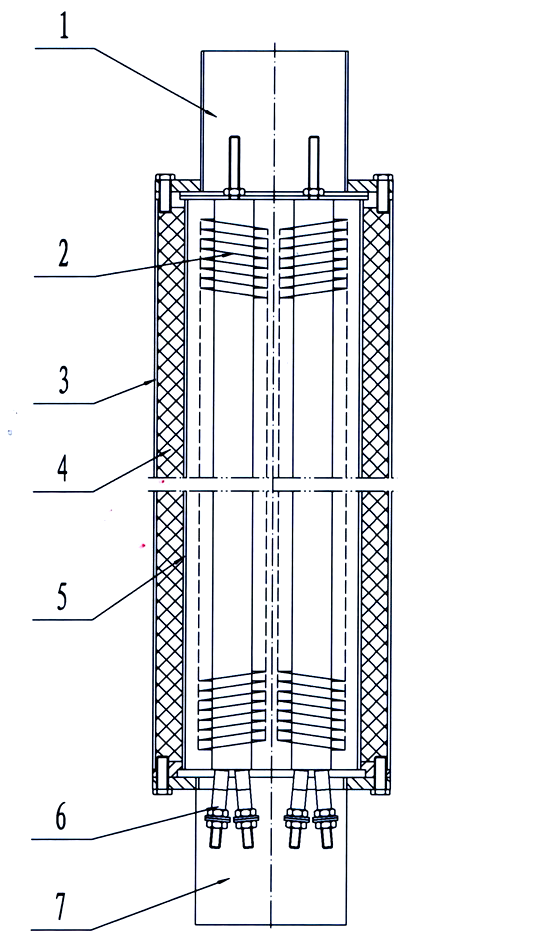

Hot Air Apparatus

- Upper tube connector

- Electric heating tube (one)

- Outer tube

- Insulating layer (asbestos)

- Internal tube

- Terminal stud

- Lower joint

The hot air device is on the right of the machine body and blast motor is in the machine. The cold air supported by fan blade is heated in the flue pipe and transformed to the pot. Electric heating tube, internal heating switch, air volume and two electric hot trays are controlled by control panel switches

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche