Efficiency Coating Machine BG-5H Operation about Starting the Machine

Efficiency Coating Machine adopt PLC control technology for the control system; the design of the whole control system is reasonable; the procedure is flexible & changeable; it can adapt different kinds of coating process requirements. It has the characters such as antijamming capability, low failure rate, convenient maintenance and major expansibility. Please refer to the following contents before using so as to the correct use & maintenance. If you have problems, please contact our company. (Note: operate any communication port in the state of outage, or part of electrical equipment such as the touching screen, communication port of PLC or printer shall be damaged.)

Start and stop

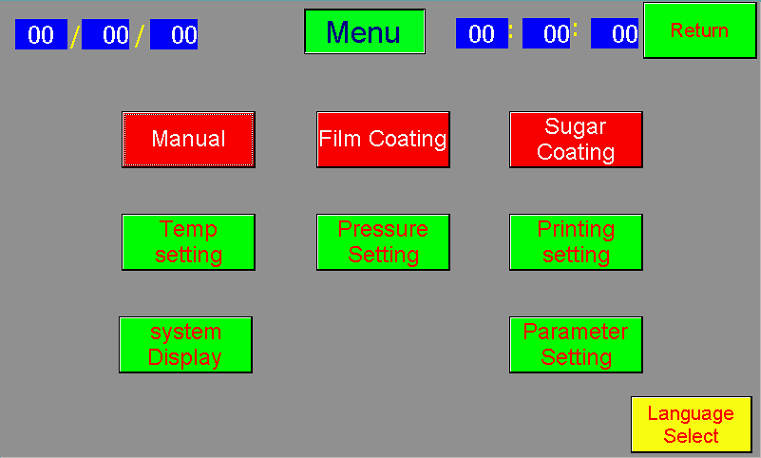

Open the power supply and press the company trademark to enter into the main menu to operate, shown as follows.

When stopping the machine, only press the emergency stop switch and close down the general power supply.

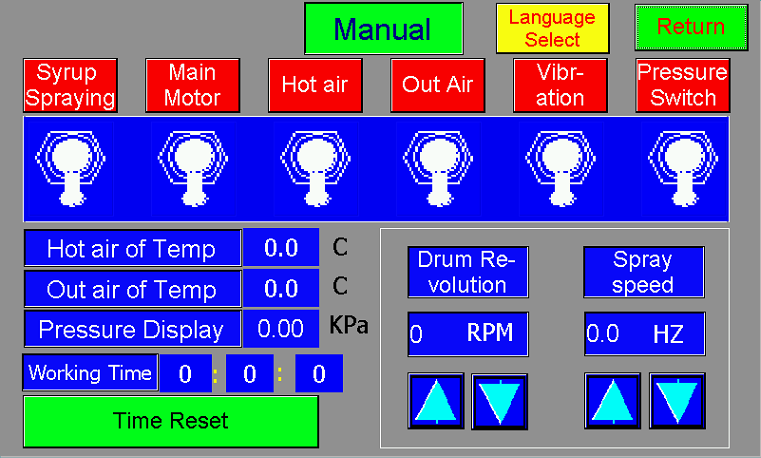

Manual operation

Press the buttons such as “spray pump”, “host machine”, “hot air”, “exhaust air”, “vibration” and “spray gun” by hands.

“Spray pump”: control the switch of peristaltic pump. The spray speed can be controlled by the up and down buttons to adjust the frequency of pump motor.

“Host machine”: control the rotation of coating roller. The rotation speed of roller can be adjusted by the up and down buttons.

“Hot air”: control the switch of hot air blower.

“Exhaust air”: control the switch of exhaust fan.

“Vibration”: control the dust removal vibration motor within the fume hood.

“Spray gun”: control the switch of spray gun.

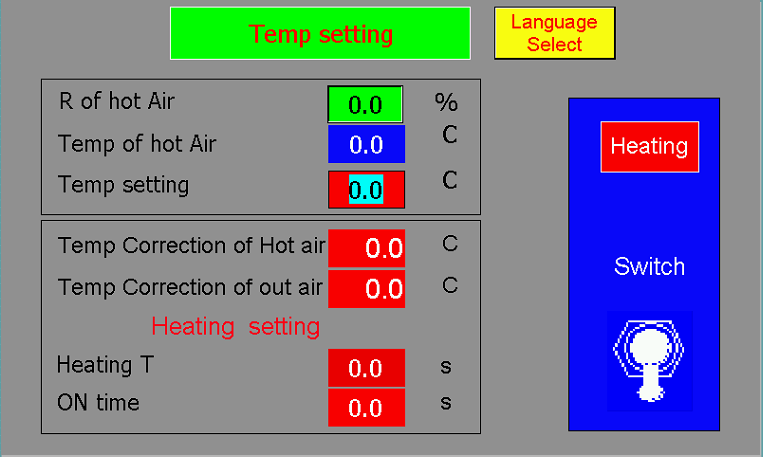

“Hot air temperature”: press the “hot air temperature” button to shown the following interface. Input your needed temperature within “Temp setting”; press “Heating” button and the temperature will increase to the set value. If the temperature shown on the touching screen doesn’t meet the practical temperature, you can correct by the inlet temperature and out temperature.

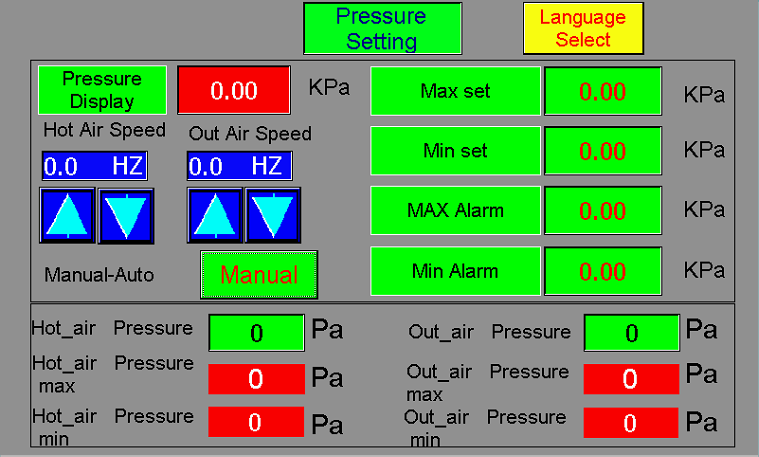

“Negative pressure display”: press this button to show the following screen. The adjusting types of negative pressure have manual and automatic types. When adjusting by hands, the frequency of hot air blower and exhaust fan can reach the needed negative pressure by the up and down keys. When carrying out the automatic adjusting, set the needed scope of negative pressure within the upper limit setting and lower limit setting, the device can adjust the negative pressure in this scope automatically. At the same time, you can set the maximum and minimum alarm value of negative pressure. It will show the alarm warning if exceeding the system. The inlet air and out air pressure difference refer to the pressure difference of hot air and exhaust air filter. When the filter is damaged or exceeds the maximum load, it will remind you to change or clean the filter.

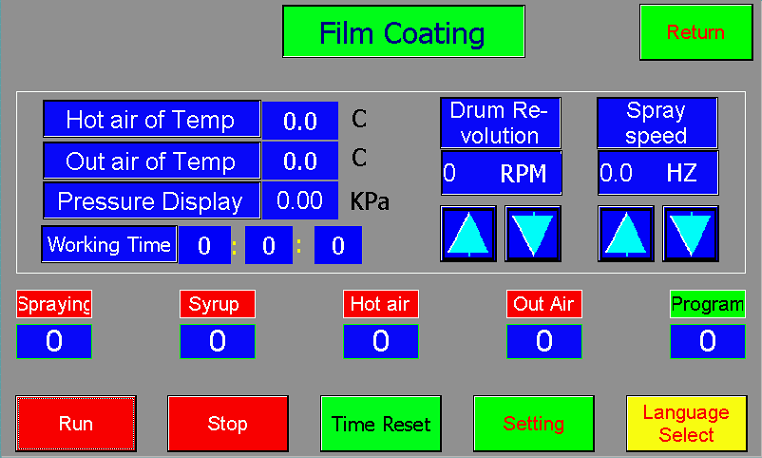

Film coating

“Hot air temperature, “exhaust air temperature”, “negative display” and the other operations within this interface are same as the above mentioned.

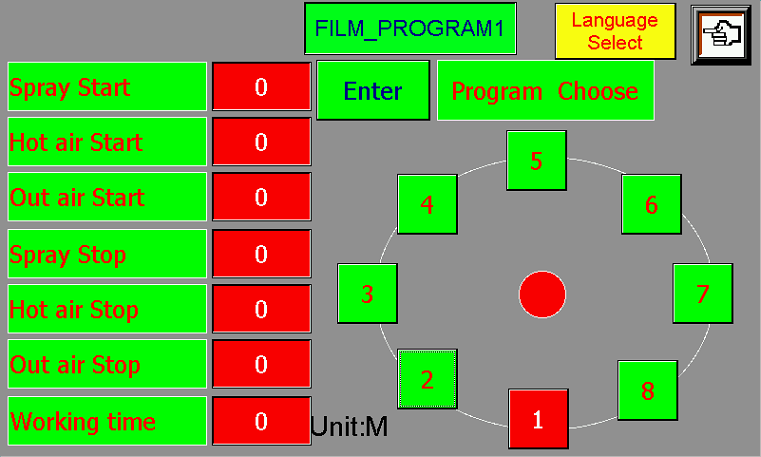

“Program setting”: the screen can be switched to the interface of Film Program 1 which can store eight settings: set the working time of host machine at first, the time is the whole time of coating, press the “modifying” key in the same row with the host machine and the screen will enter into the modifying screen. The figures will flicker by pressing “setting”, at that time, input your needed working time on the keyboard. The time unit is minute. If you input fault number, you can press “CLR” key. If you input correct number, you can press “ENT” key. And then you can set the other data by the above mentioned same methods. “Start delay” refers to “spray”, “hot air” and “exhaust air” begin to work as per the set time after the working of host machine. “Stop delay” refers to “spray”, “hot air” and “exhaust air” will stop when they operate to the set delay time. Set the other program interfaces by the figures shown on the touching screen. You can operate as per the above mentioned steps.

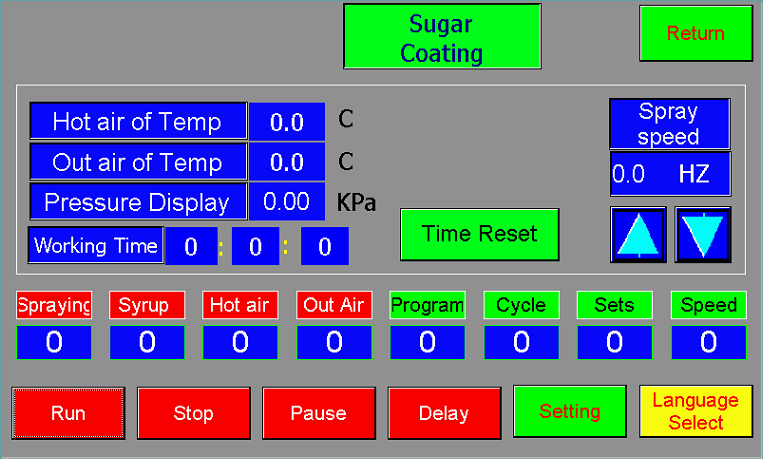

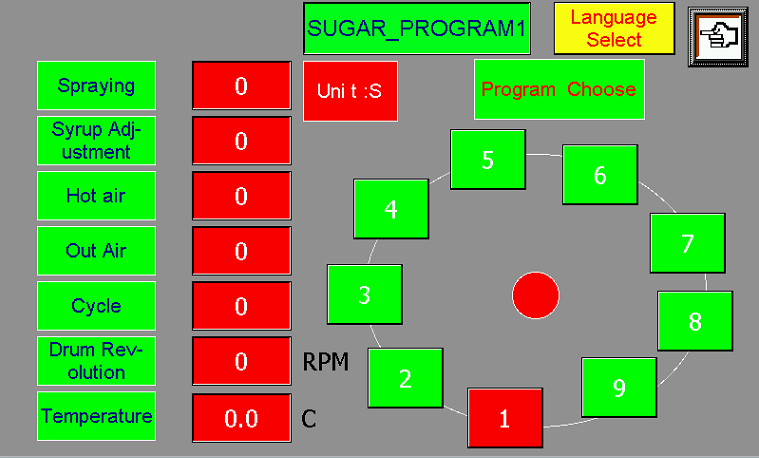

Automatic sugar coating

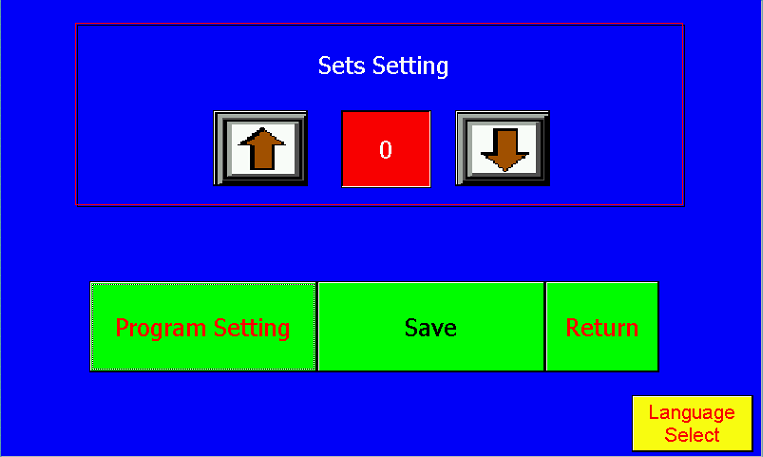

The operation of this interface is similar with that of film interface. The operation of “hot air temperature” and “negative pressure” is same as the above mentioned. The spray speed can be adjusted by the up and down keys. The working time of “spray”, “homogenate”, “hot air” and the other programs can be shown at the bottom of the interface. The screen can be switched to the interface of “set number selection” by pressing “parameter setting” key. You can choose the program number by pressing the up and down keys. You can storage nine programs in total. Press “sugar-coating” interface. Set the working time of spray at first. Press the “setting” key and the figures will flicker and then you can input your needed parameters on the left keyboard; confirm by pressing “ENT”; jump to the next parameter setting automatically. The rest can be done in the same manner to keep the parameters. Begin to operate programs. Continue to work after stopping work temporarily, which also can extend each working conditions.

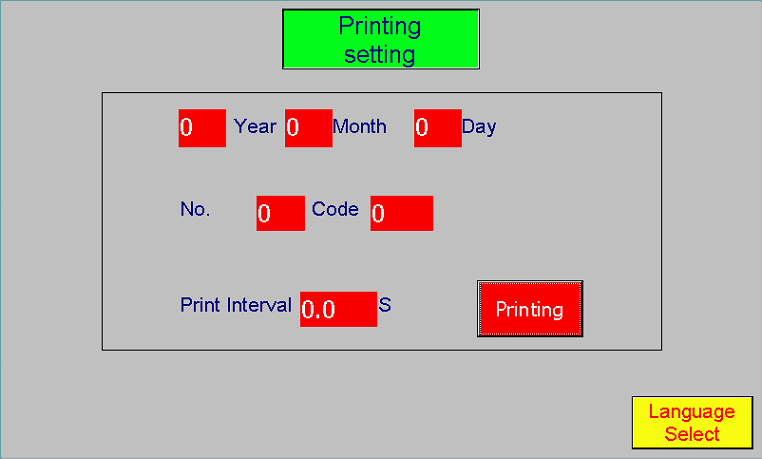

Print setting

After setting the time, batch number, code number, print interval and the other parameters within this interface, press the “print” key and the printer will print the currently operating parameters of machine once within the interval time so as to test the working conditions of coating.

Water draining

Press this key and the magnetic valve of water pond outlet begins to work. Open the drain valve and the water will be discharged to floor drain.

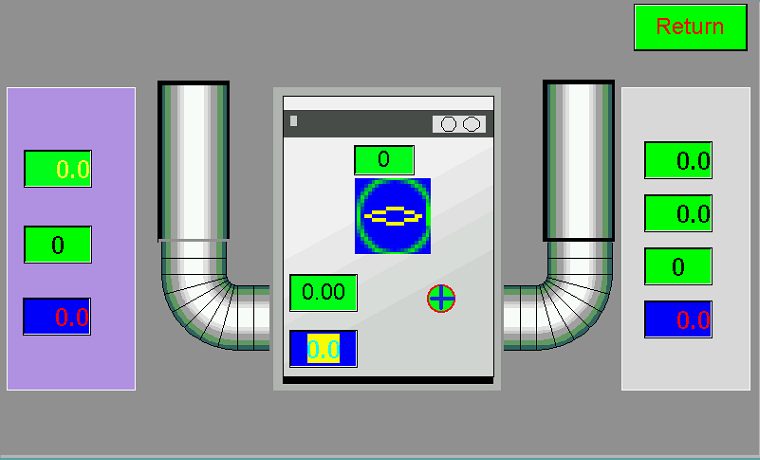

System display

This interface is the dynamic display interface of operating coating machine. Any parts appear the problems or stop, which can be seen in the interface.

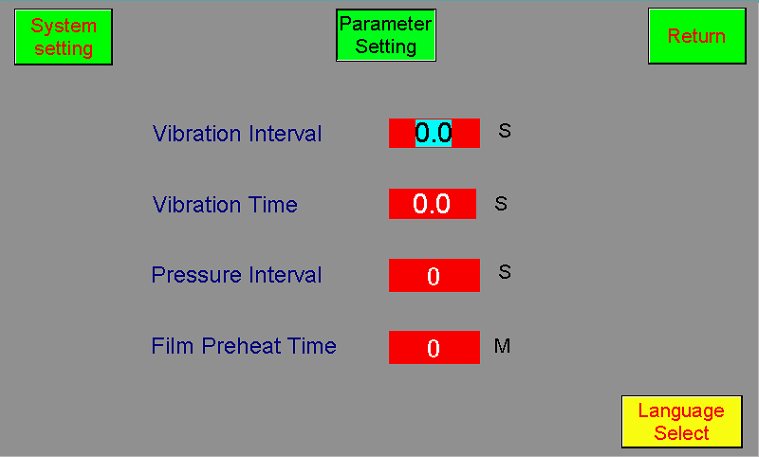

Parameter setting

“Vibration interval”: refers to the vibration interval time.

“Vibration time”: refers to the time needed by the function of vibration dust removal of exhaust fan.

“Spray gun interval”: set the frequency of cleaning the gun.

“Preheat time”: this function is used at the time of automatic package film garment. After setting the time, carry out the preheating for the materials before work.

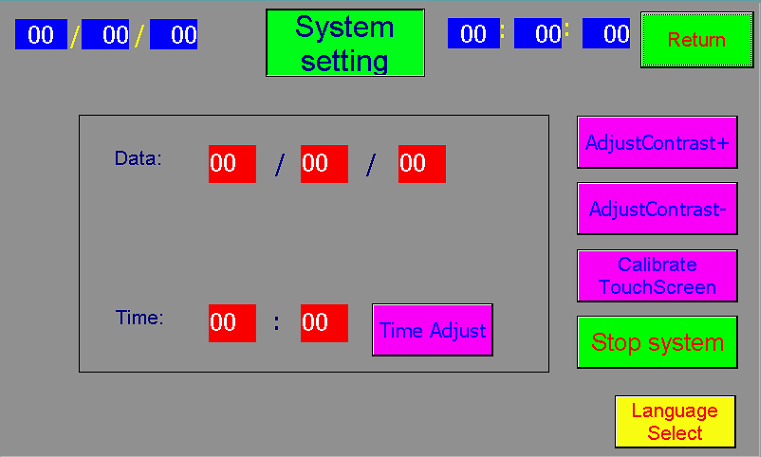

Press “System setting” key to show the following interface.

“Time calibration”: set the date and time.

“Contrast+”: increase the brightness of touching screen.

“Contrast-”: reduce the brightness of touching screen.

“Touching calibration”: calibrate the accuracy of touching.

“Stop running”: press this interface to enter into the original interface at the time of opening the touching screen.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche