Vibrating Granulator YK60: Introduction & Structure

Introduction

This vibrating granulator makes use of the rolling motion of rotating barrel to granulate the wet powder materials into granule by sieve. It can also be used to crush agglomerate materials into small granules directly.

In chemical medicine field, the oscillating granulator machine YK60 can be used for granulating the mixed powder into granule, and then compressed into tablet after being dried. The machine also can be used for granulating the coagulated material that is formed during storage or during chemical processing. In food industry, it is used to deal with the candy and sugar mixture as well as barley milk products. In other industries, this device can be used to granulate such as porcelain and plastic mixtures into forming granules. However, it is not suitable for solid, fluid medium, paste or pulverizing. And the mesh number of sieve should be prepared by users, according to the size of granule.

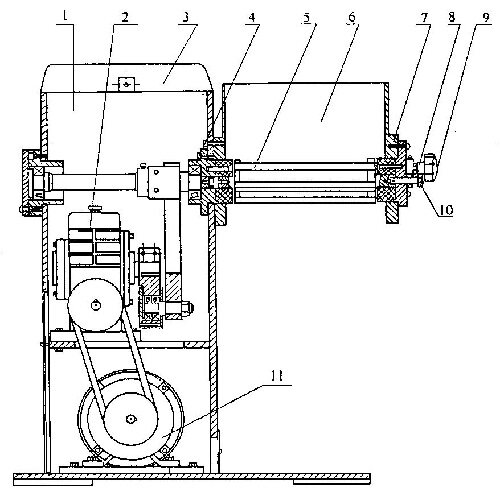

Structures

| 1. Fuselage | 2. Reducer Box | 3. Cover |

| 4. Middle Bearing Caps | 5. Roller | 6.Plus hopper |

| 7. Front Bearing | 8. Ratchet Pawl | 9. Hand wheel |

| 10. Knurling screwing | 11.Motor |

Structure Description

- This machine is cuboid, which consists of bearing frame, reducer box and machine seat. The hopper is connected with bearing frame, and stretch out of the machine. The design of front-end is standing-out, so when you put the machine in the ground, it is stable. You don not need to install the machine, because it is free to be placed indoors.

- Particle devices: The rotary roller lying device is installed below the hopper. There is bearing support before and after it. It transmits by rack, and do turn down movement. The front bearing is activities. When you assembly and disassembly it, you just need to unscrew three screws, then the front bearing and rotary roller can turn out. The both sides of rotary roller apply symmetrical axis convex section, and it is easy to assemble and disassemble.

- Sieve tube clip: Setting up on the both sides of rotary barrel, manufactured by steel pipe, there is a long slot in the middle, and the both sides of sieve are embedded into the slot. Turn the hand wheel to make the sieve wrapped in the cylindrical rotary barrel. There is ratchet in the hand wheel, so you can adjust tightness.

- Reducer Box: Apply worm gear driving, and the speed ratio:1:30. The box can store oil, ensuring good lubrication and no noise of the tooth rod, gear and worm gear. The outer end of worm gear installs an eccentric rod, which making the tooth bar does reciprocating movement, and the gear shaft do rotary movement.

- Machine seat: Motor installation plate is connected with the seat, and the other side is connecting with the nut. When rotating the hand wheel to adjust the rotation of screw, nut is driven under the motor plate in order to transfer V-belt tightness.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche