YF3-1 Automatic Powder Grinder: Installation & Operation

Installation:

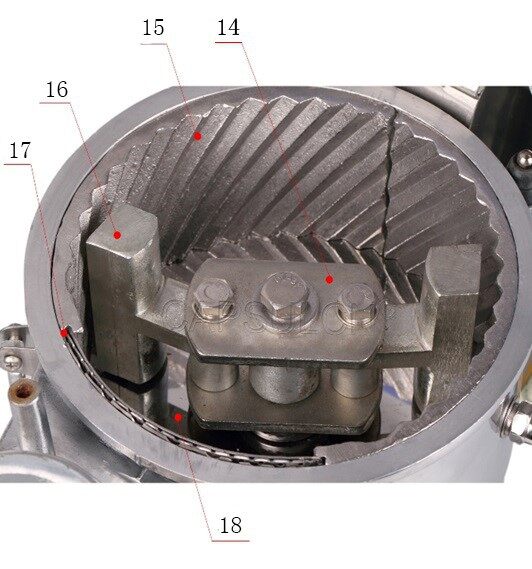

Before installating YF3-1 powder grinder, the operator needs to know its structures well.

1. Please check if there is any debris in the pulverizing chamber (18) before operating, place the filter for the required fineness in order, and tighten the butterfly nut (5) on the pulverizing chamber.

2. Observe whether the machine is running with abnormal vibration and sound, and whether the pointer of the ampere meter (13) points to zero. Then slowly feed the material into the feeding hopper (1). During the operation, please pay attention to the pointer of the ampere ammeter. If the electric current is under 5A, keep feeding; if the electric current is 10A, stop feeding until the pointer goes back to the left. The ampere meter reflects the working condition of the motor. The operation will directly affect the service life of the motor. Therefore, please be patient when feed.

3. If the machine needs to pulverize continuously for a long time, please ensure that the expanding air inlet (3) is well opened for air suction, so as to speed up discharging and cool the pulverizing chamber (18). At the same time, please pay attention to the temperature resistance of the pulverized material, so as to avoid component changing and carbonization. If necessary, stop the machine for pulverizing until it is cooled.

4. After the pulverizing, make the machine worked for a few minutes with expanding air inlet (3) well opened, and then stop the machine for discharging. When pulverizing different materials, change the filter; then turn on the machine. The air inlet (3) well opened, the air flow will blow out the residue in the pulverizing chamber to ensure the purity of the pulverized material.

Operation:

When pulverizing crude medicine material:

1. Put in the pane (A) and the backstop (C) into the guide plate of the filter unit (17) in the order of A-C as the image above. (the pane shall be inside while the backstop shall be outside.)

2. Put the dust collecting bag on Interface of dust collecting bag(6) and material collecting bag on interface of collecting bag(7).

3. Lock the upper cover (4) with a butterfly nut(5).

4. Connect the machine to the power supply and turn on the power switch (11) to rotate the pulverizing blade set (14) for pulverizing.

When pulverizing fine medicine material:

1. Put in the pane (A), the screen (B) and the backstop (C) into the guide plate of the filter unit (17) in the order of A-B-C as the image above.

2. The following steps are the same when pulverizing crude medicine material.

Precautions:

1. The medicinal material to be pulverized needs to be dried before pulverizing. Fiber-based pieces should be cut to 2.5cm or smaller before feeding, so as to avoid blade being winded by long-fiber.

2. Do not feed until the pulverizing blade set (14) rotates.

3. Please feed slowly and pay attention to the pointer of the ampere meter (13). For a machine of 220V, the electric current shall under 10A, and for a machine of 110V, the electric current shall under 15A. If the electric current is higher than that, stop feeding until it goes down.

4. If there is too much material, the current overload protection switch (12) will be ejected and turn off the power. For this situation, please follow the steps below:

- Turn off the power switch (11).

- Open the upper cover (4) and take out the filter unit to remove all the medicinal material from the pulverizing chamber.

- Press the overload protection switch.

5. Every time before operation, check whether the pointer of the ampere meter (13) points to zero.

6. The filter shall be equipped according to the fineness of the finished product.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche