6 Major Applications of Capsule Filler

The encapsulation machine plays an important role in capsule making. It helps fill the capsules with materials that contain API (active pharmaceutical ingredient). Thus, it is the key component of capsule processing.

This article has listed the 6 major applications of capsule filling machines. Hopefully, it can help you select the right capsule filler parts, such as hoppers or capsule filling systems.

1. Filling powders

Capsules with powder is the most common type of solid dosage form. It is the fine, dry particles produced by grinding, pounding, or crushing solid substances.

Generally, filling powders is the most common application of capsule filling machines. It can be achieved by manual encapsulators - though the manual type is not as efficient and accurate as the automatic capsule filler.

This results in the simpler structure design of powder capsule fillers, as well as their hoppers and dosing systems.

2. Filling tablets

Compared with other fill materials, tablets tend to be larger in size. A capsule can only contain one or several tablets. The number of tablets is determined by the size of the capsule.

Of 6 applications of capsule filling machines, filling tablets is not commonly seen. But in some clinical trials, if some tablets are an irritant to the stomach, then they are likely to be ejected into capsules.

To fill tablets into capsules, you want to source a reliable automatic capsule filler with special dosing systems.

3. Filling granules

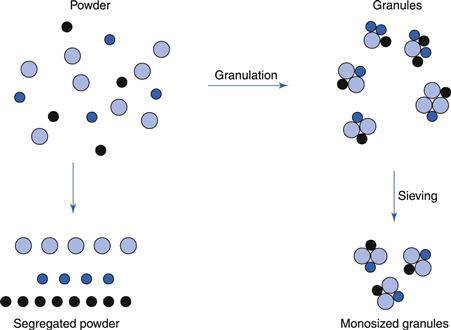

Like powders, granules are also the most commonly used solid dosage form in the pharmaceutical industry. They are typically larger particles created by gathering together powder particles. The process of creating granules by aggregating powder particles is known as granulation.

Due to the particle size difference or component density difference, powder segregation may occur in the hoppers or bulk containers. To prevent segregation in drug production, granules are often used to ensure content uniformity.

Typically, granules are mainly used for high-dose, low-potent drugs. The coating on the granules is gastric-resistant and should not be damaged in the packaging process. Thus, the capsule filling machine used to fill granules should have a unique design to protect their coating.

4. Filling pellets

Pellets are small, free-flowing, spherical-shaped units made from a group of fine powders or granules of drugs through pelletization.

In recent years, pellets have become very popular across the industry. With the aid of coating, they can be used for site-specific drug delivery. Besides, pellets are so versatile that they can be combined with other incompatible ingredients.

Despite a good drug administration method, filling pellets is slower than filling powders. Today, many capsule filling machines can fill either powders or pellets. But when filling pellets, you should adjust the dosing system, so that automatic capsule fillers can suit the pellet filling well.

5. Filling liquids

Filling liquids into the capsules consists of two steps: liquid filling and capsule sealing.

For the liquid filling, the automatic capsule fillers should be equipped with liquid filling stations. Typically, they adopt servo-controlled liquid pumps, which are precise enough to fill liquids of 100 mg to 1.5 grams. On top of that, the capsule filler can fill liquids in a wide range of viscosity spectrum.

For capsule sealing, two ways, either sealing or banding, are available for the process.

When sealing the capsules, the sealing solution is applied through a fine spray onto the joints of the caps and bodies. When banding the capsules, the banding solution is applied through a rotating wheel.

6. Filling Combinations

Sometimes, a combination of products, such as liquids and semi-solid substances, needs to be filled into capsules. At these times, you really want to customize your capsule filling machines from a reliable supplier. Because they are capable of providing tailor-made machines to meet your specific filling needs.

Apart from the versatility of your capsule fillers, another thing you need to note is the formulation of your capsules. They should meet certain criteria so that the final product can conform to cGMP.

The bottom line

Now you have a clear view of the 6 typical applications of capsule filling machines. To meet your unique capsule filling requirements, you really need to study the substance you want to fill and the capsule dosage forms used in capsule fillers. Then cooperate with the supplier who can bring you the best capsule filling machine.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche