How to Troubleshoot Your Capsule Filling Machine

Every capsule filling machine is bound to fail at some point. When simply restarting the equipment isn't enough to get it back into service, we must figure out the cause and fix it. Simply put, we need troubleshooting. Yet, troubleshooting isn't just for fixing machinery that has stopped working entirely. We also use it when your machine is not functioning as anticipated.

No matter your capsule machine type, capsule filling machines can come across problems that affect their efficiency. To ensure that your capsule filling machine is operating at peak performance, learning more about how to troubleshoot common problems that may arise is important.

Have issues with capsule filling machines? You've come to the right place. In this article, we will delve into a few troubleshooting tips and tricks to keep your capsule filling machine running smoothly.

What are common capsule filling machine problems? Are there any effective solutions to fix them? Those may be the most frequently asked questions proposed by capsule filler users.

Today, not just complex machinery problems will be taken care of here. Even if you're using a manual capsule filling machine, we will share useful insights and steps to help you navigate your capsule filler troubleshooting. Let's get started!

Tips to Troubleshoot a Manual Capsule Filling Machine

A manual capsule filling machine typically consists of a body plate, a middle plate, a cap plate, an alignment plate, a tamper, a spill guard, and a spatula. Let's take a look at some common problems of these parts and their solutions.

|

Problem |

Possible Cause |

Solution |

|

The dowel pin falls out. |

Temperature changes. |

Replace the dowel pin or glue it to the plate. |

|

Transport vibration. |

Add adhesive to the pins or reduce the hold size to lock the dowel pin. |

|

|

The dowel pin cannot be pressed into the body plate hole. |

Incorrect pin spacing. |

Replace the tamper. |

|

Temperature changes. |

Replace the tamper. |

|

|

Powder spills. |

The spill guard is deformed and uneven. |

Lay it flat and blow it with hot air. Remember to keep it flat when not in use. |

|

The capsule body falls out, and powder spills. |

The body plate height is too high. |

Adjust the upper layer height of the body plate to be 1mm away from the capsule body. |

|

The alignment plate is not placed flat. |

The body plate screw comes out and presses against the alignment plate. |

Adjust the body plate screw and screw countersink. If it is easy to clean, the nut needs to be adjusted as well. |

|

The capsule body doesn’t sit snugly in the hole. |

There are burrs and residues in the holes of the body plate. |

Clean and disinfect the body plate before the first use. Remove the burrs and residues in the holes. |

|

Dented capsule body. |

The body plate is too thin. |

Replace the body plate. |

|

The capsule cannot be closed properly. |

The middle plate is too thick. |

Replace the middle plate. |

|

The capsule is not locked tightly. |

The hole in the cap plate is too deep. |

Replace the cap plate. |

|

The capsule is scratched and damaged. |

The middle plate is not placed properly. |

Shake gently after placing the plate. |

|

The locking ring is severely deformed. |

Adjust the storage environment and temperature and humidity. |

How to Fix Problems with Semi-Automatic Capsule Filling Machines

Compared with manual capsule fillers, semi-automatic capsule filling machines come with a certain level of automation. Yet, they may encounter various problems during operation. The following are some solutions that can help you address these issues.

|

Problem |

Possible Cause |

Solution |

|

Capsules fly out of the machine. |

Too high vacuum pressure. |

Adjust the vacuum pressure. |

|

Two capsules are fed into the filling ring at the same time. |

The gate of the capsule sowing mechanism opens too early. |

Adjust the sorting block of the sowing mechanism to align capsules to the center of the filling ring’s holes. |

|

Capsules are not fed into the filling ring. |

The filling ring’s holes fail to align to the capsule sowing mechanism. |

Realign the filling ring and the capsule sowing mechanism. |

|

Capsule caps and bodies fail to separate. |

Insufficient vacuum pressure. |

Increase the vacuum pump pressure. |

|

Capsule defects or wrong capsule sizes. |

Replace the capsules. |

|

|

The fill weight is not uniform. |

The filling ring is not in the correct position. |

Reinstall the filling ring. |

|

Low powder level in the hopper. |

Refill the powder hopper. |

|

|

The tooling is damaged. |

Replace the tooling such as the filling ring, horizontal sorting fingers, magazine complete, or sorting block. |

|

|

Inconsistent dosing. |

The rotational speed of the filling ring fails to match up to the rotational speed of the auger inside the powder hopper. |

Adjust the rotational speed of the filling ring and auger. |

|

The air pressure is too low to make the filling ring rotate. |

Check and adjust the air pressure. |

|

|

Capsules are too tight or too loose. |

The air pressure is either too high or too low. |

Adjust the air pressure. |

|

Too high moisture content of the powder. |

Reduce the environment's humidity or dry the powder. |

|

|

Capsules are not fed via the magazine complete. |

The magazine complete is clogged. |

Disassemble the magazine complete and clean it. |

|

The magazine complete is not aligned properly. |

Adjust the magazine complete. |

|

|

Capsules fail to be sealed. |

Capsules or powders are stuck in the filling ring. |

Clean the filling ring. |

|

Capsules are damaged. |

Overdosed powder. |

Speed up the rotary table. |

|

Use capsules of larger sizes. |

||

|

Fill with less powder. |

||

|

The capsule caps and bodies are too tight. |

Decrease the capsule sealing force. |

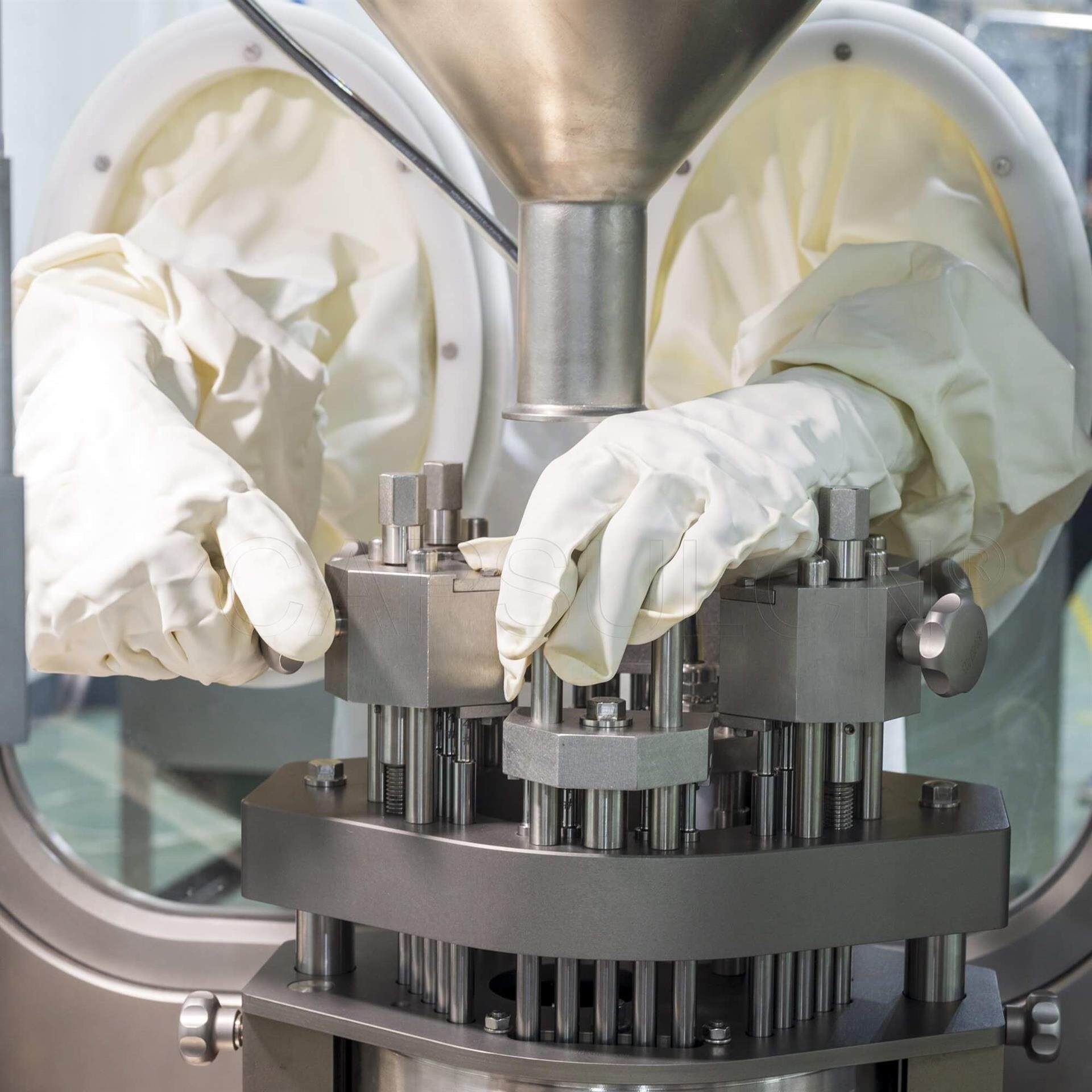

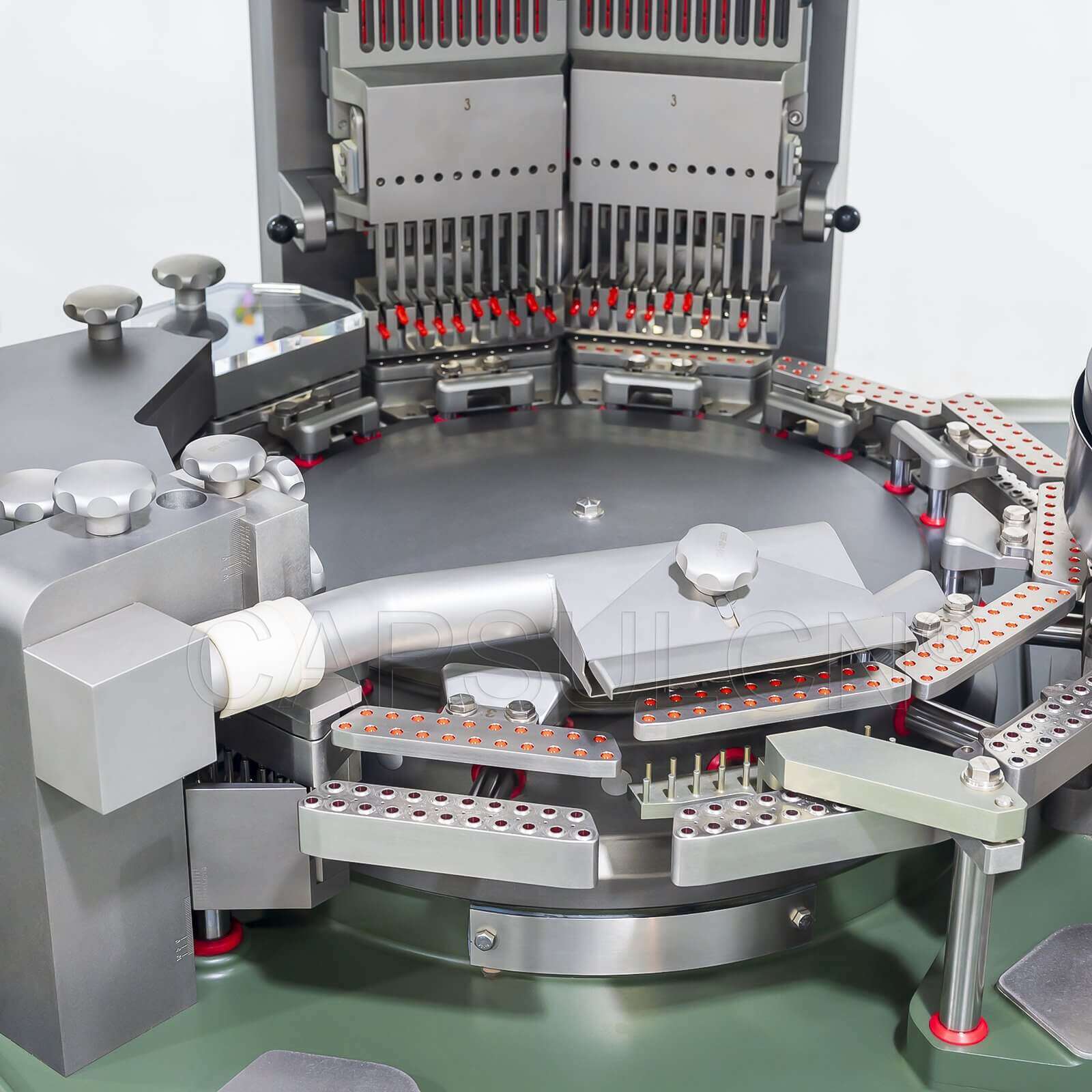

Troubleshooting Automatic Capsule Filling Machine Issues

Like any complex machinery, an automatic capsule filling machine may encounter various technical issues. If your machine is experiencing the following problems, we hope these solutions will help you out.

|

Problem |

Possible Cause |

Solution |

|

Capsules stick together. |

The temperature is too high during transport or storage. |

Adjust the temperature. |

|

Capsules are squeezed or split open. |

Powder overflows from the capsule bodies. |

Adjust the filling speed. |

|

Capsule caps and bodies are squeezed. |

The stroke of ejector pins is too large during capsule closing. |

Adjust the stroke. |

|

Capsules fail to be separated. |

Low vacuum pressure or the device is clogged. |

Increase the vacuum pressure or remove the clog. |

|

Capsules fail to be fed into the segment bores. |

The orientation device of the capsule feeding unit is not installed properly. |

Reinstall the orientation device. |

|

Capsules deform. |

The upper and lower segments are not aligned. |

Realign the upper and lower segments. |

|

Too much capsule waste. |

The capsule feeding unit is not cleaned properly. |

Clean the capsule feeding unit. |

|

Capsule caps fail to be separated at the correct station. |

The vacuum pressure is not set correctly. |

Adjust the vacuum pump. |

|

All capsules are damaged during closing. |

The closing station is not adjusted properly. |

Adjust the closing station. |

|

The diameter of the closing pins is too small. |

Replace them with larger sizes. |

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche