Dosator Vs. Dosing Disc: Comparing Two Capsule Filling Machines

Today, capsule filler machine plays a key role in the pharmaceutical and nutraceutical industries. Among them, dosator and dosing disc fillers are the two most popular types of encapsulation machines.

But what's the difference between them? Which is the right one for you? If you're looking for a capsule filler to improve your business, you're in the right place. In this article, I'm going to compare dosator vs. dosing disc to help you out. Let's get started!

What Are They?

A dosator capsule filling machine is used to dose hard shell capsules by means of dosator technology. For the purpose of filling capsules, this method either employs mechanical or vacuum compaction and discharge, or vacuum suction and discharge.

A dosing disc capsule filling machine, also called the tamping pin capsule filling machine, uses tamping pins to fill capsules. These tamping pins move up and down through a powder bed to transfer a dose into a dosing disc.

The Similarities Between Dosator and Tamping Pin Capsule Filling Machines

Before comparing dosator vs. dosing disc, let's take a look at some of the most basic similarities between them.

Forming Powder Plugs for Capsule Filling

The piston-tamp principle operates most modern automatic capsule filling machines. Both the dosator and dosing disc fillers use pistons or tamping pins to compress the powder into plugs and eject the plugs into the capsule bodies.

Capable of Handling Various Capsule Sizes

Both the dosator and dosing disc filling systems are capable of filling capsules of all standard sizes (from size 000 to 5). So, they can help you achieve the manufacturing for small-scale clinical trials or on a large scale. However, note that these automatic machines are only suitable for filling joined capsules.

Capsule Filling Applications

When it comes to capsule filling applications, If you want to fill hard shell capsules with powder, pellets, granules, or micro-tablets, both the dosator and dosing disc fillers are solid choices. Of course, the production yields on these machines vary with the solid dosage forms. Also, the filling speed is determined by the nature of the fill materials.

High Accuracy and Efficiency

These two automatic capsule fillers perform way better than manual and semi-automatic encapsulators in terms of filling speed and dosing accuracy. And on top of that, the design of both machines allows them to integrate into a production line. They can effectively collaborate with other peripheral machines like a capsule polisher, capsule sorter, empty capsule ejector, and dust extractor.

The Differences Between Dosator and Tamping Pin Capsule Filling Machines

Now that you have built a rough idea of the similarities between the dosator and dosing disc encapsulators, let's dive into the comparison between them.

Working Principle: Dosator Vs. Dosing Disc

The biggest difference between these two filling machines lies in the working principle. Read on to find out how they work.

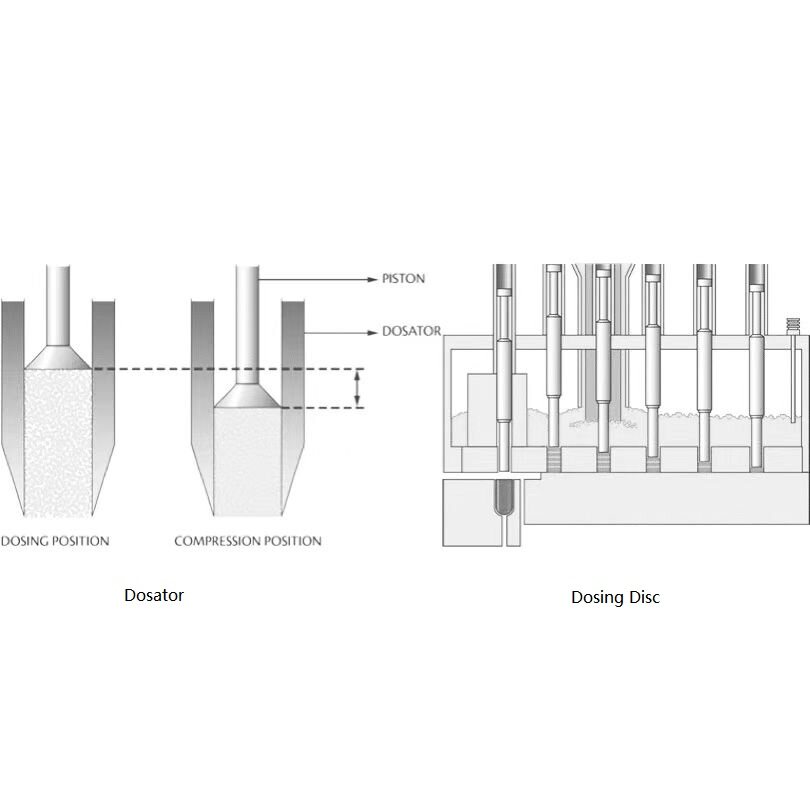

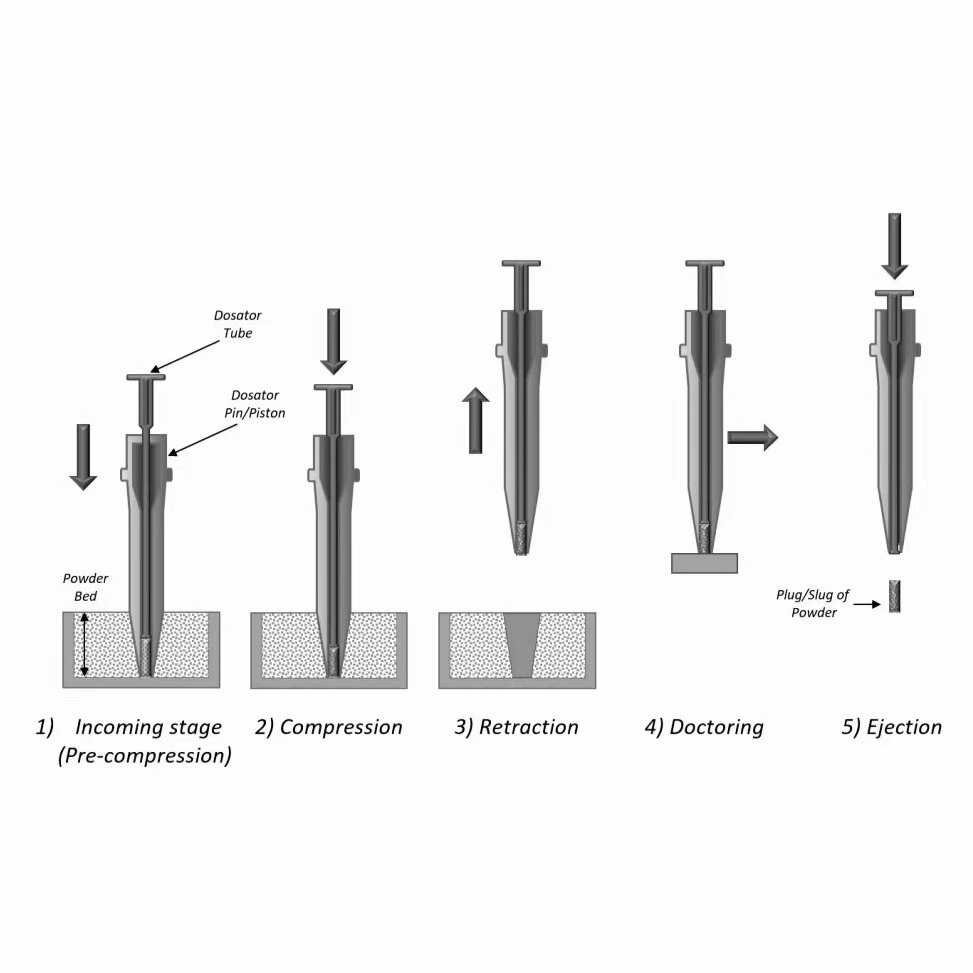

Dosator Capsule Filling Machine: This dosing system consists of a dosator tube and a dosator piston. The process is divided into five stages:

1) The dosator descends into the powder bed and captures a dose to hold it in the cavity;

2) The dosator piston is pushed down to compress the powder to form a plug;

3) The dosator retracts from the powder bed with the plug inside;

4) The doctoring is performed to remove unwanted powders at the dosator nozzle tip;

5) The dosator indexes the empty capsule body to eject the plug.

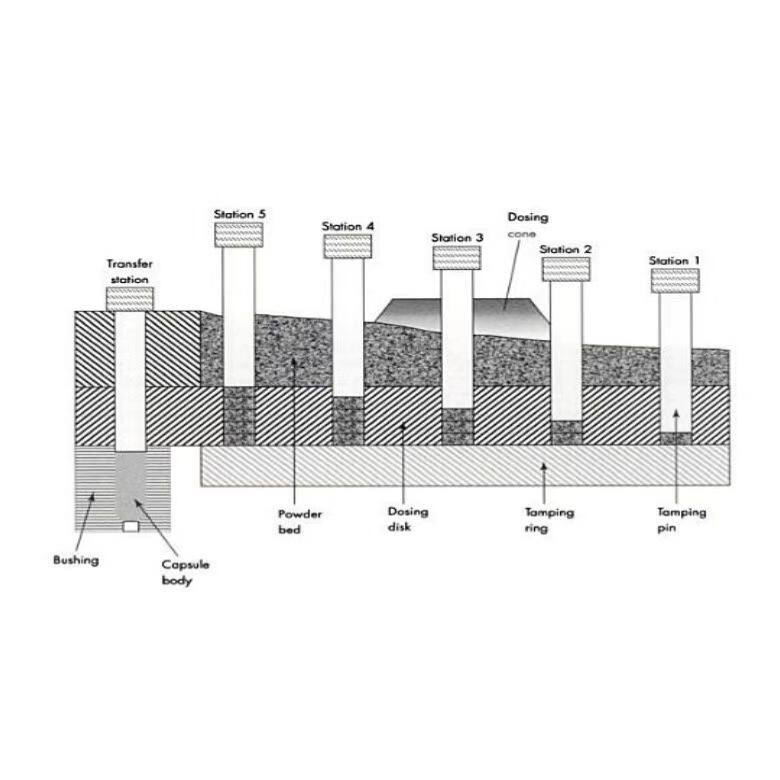

Tamping Pin Capsule Filling Machine: The tamp filling system comprises a powder bowl, tamping pins, a dosing disc with six sets of holes, and a tamping ring. It includes five tamping stations and one transfer station. The dosing process goes like this:

The dosing disc indexes the holes beneath six sets of tamping pins. The powders flow into the holes during indexing. These pins descend to compress the powders inside the holes to form plugs at five tamping stations. At the transfer station, the pins move down to push the plugs out of the holes into capsule bodies.

Capsule Filling Applications

Aside from filling the solid dosage forms mentioned earlier, the dosator capsule filling machines can precisely dose powder into dry powder inhalers (DPIs).

A DPI is a capsule-based device designed to deliver medications to the lungs in the form of dry powders. It contains pre-metered doses in the capsule. Since each dose is at a very low weight, the DPI filling requires specialized equipment.

The dosator system is capable of filling very small amounts of powders into each capsule. It can use a controlled force to compact and transfer the powder to the capsule. Because of this, the powder inside the capsule is more likely to be kept free-flowing.

The tamping pin capsule fillers obviously can't handle such a micro-dosing operation. However, today most modern automatic capsule filling machines employ this dosing technology because it offers ever-better filling accuracy, production efficiency, and product quality for large-scale manufacturing.

Wrap-Up

This Dosator vs. Dosing disc comparison should help you better understand these two automatic capsule filling machines. While both are the best options for leveling up your production, our vote goes to the dosing disc system.

Thanks to its popularity, there is a wide selection of tamping pin capsule filling machines out there. So, finding the right equipment for your business needs can be much easier.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche