How to Import Capsule Filling Machine from China: A Complete Guide

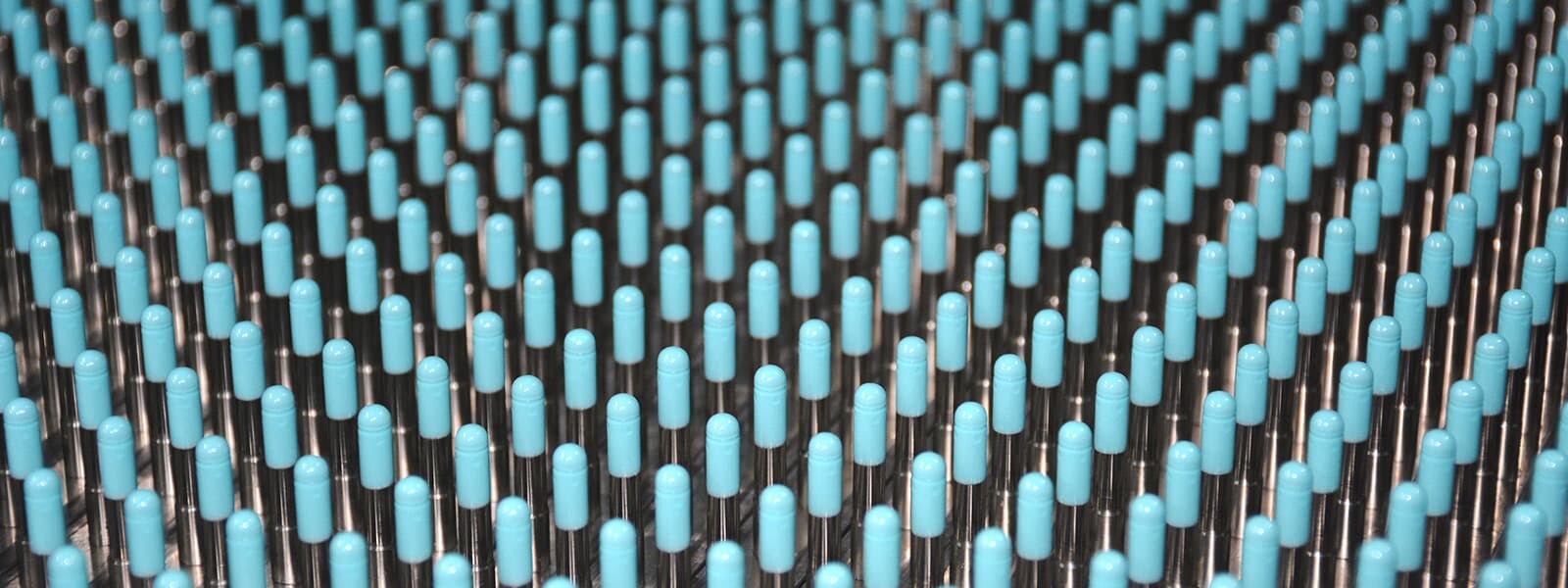

Capsule filling machine plays a crucial role in the pharmaceutical industry. They are used to fill hard capsules with various powders, pellets, and granules. Importing capsule filling machines from China can be a cost-effective solution for pharmaceutical companies looking to expand their operations. In this comprehensive guide, we will explore the benefits of importing capsule filling machines from China, where to find reliable manufacturers, and how to choose the best machine for your needs.

Since this importing guide is a little bit long, below are the links that help you position the different sections quickly:

The Importance of Importing Capsule Filling Machines

Capsule filling machines are important in pharmaceutical manufacturing. They are used to fill hard capsules with precise amounts of medication, ensuring consistency in dosage and efficacy. Without these machines, the capsule filling process would be time-consuming, prone to errors, and costly.

Where to Import Capsule Filling Machines from China

China has a vast manufacturing industry spread across different regions. When sourcing for capsule filling machines, it is essential to identify the top cities and trade shows that offer reliable and high-quality products.

1. Overview of China's Manufacturing Industry

China's capsule filling machine manufacturing industry has developed rapidly in recent years. The industry has been growing at an average rate of 15% per year, making China one of the world's largest capsule filling machine manufacturers.

China's capsule filling machine manufacturing industry is mainly concentrated in the eastern coastal regions, especially in the provinces of Zhejiang, Shanghai, and Jiangsu. The city of Ruian in Zhejiang Province is known as the "Hometown of Chinese Packaging Machinery" and has become a major production base for capsule filling machines.

The production of capsule filling machines in China can be divided into manual, semi-automatic, and automatic types. Manual capsule filling machines are mainly produced by small manufacturers, while large and medium-sized manufacturers mainly produce semi-automatic and automatic capsule filling machines.

The quality of capsule filling machines in China has been greatly improved in recent years. Many Chinese manufacturers have invested heavily in research and development, making great progress in technology and innovation. Many Chinese capsule filling machines have obtained international certifications such as CE and FDA.

In terms of market demand, the domestic market is the largest market for Chinese capsule filling machines. With the rapid development of the pharmaceutical industry in China, the demand for capsule filling machines is increasing. In addition, Chinese capsule filling machines are also exported to many countries and regions, including Southeast Asia, Europe, and America.

In summary, China's capsule filling machine manufacturing industry has achieved rapid development in recent years, mainly concentrated in the eastern coastal regions. With the continuous improvement of technology and innovation, Chinese capsule filling machines have become more and more competitive in the global market.

2. Top Cities for Sourcing Capsule Filling Machines

When importing capsule filling machines from China, some of the top cities to consider include Ruian, Shanghai, Guangzhou and Shenzhen. These cities are home to many reputable manufacturers with extensive experience in producing high-quality machines.

There are several top cities in China for importing capsule filling machines:

1. Ruian:

Located in Wenzhou, Ruian is known as the "Capital of China's Packaging Machinery" and is home to many top capsule filling machine manufacturers like iPharmachine.

2. Shanghai:

As one of the largest cities in China and a major center for international trade, Shanghai is a hub for importing all types of machinery, including capsule filling machines. Many foreign companies have set up their offices and factories in Shanghai, making it a convenient location for international business.

3. Guangzhou:

Located in the southern part of China, Guangzhou is a major manufacturing and trading center, particularly for pharmaceutical and medical industries. Many capsule filling machine manufacturers have set up factories in this city due to its convenient location and favorable business environment.

3. Popular Trade Shows for Finding Chinese Manufacturers

If you're interested in finding a reliable Chinese capsule filler manufacturer, attending trade shows is a great way to connect with potential suppliers and learn more about the industry. Here are some popular trade shows for finding Chinese capsule filler manufacturers:

1) China International Pharmaceutical Machinery Exposition (CIPM)

CIPM is one of the largest pharmaceutical machinery exhibitions in the world, with over 1000 exhibitors and 70,000 visitors from more than 100 countries. The show takes place twice a year, in the spring and fall, in different cities throughout China. At CIPM, you can find a wide range of pharmaceutical machinery, including capsule fillers, and meet with suppliers from all over China.

2) Shanghai International Pharma Machinery Exhibition (P-MEC China)

P-MEC China is part of the larger CPhI China exhibition and focuses specifically on pharmaceutical machinery and equipment. The show is held annually in Shanghai and attracts more than 3,000 exhibitors and 70,000 visitors from around the world. At P-MEC China, you can find a wide range of pharmaceutical machinery, including capsule fillers, and meet with suppliers from all over China and beyond.

3) Canton Fair

The Canton Fair is the largest trade fair in China and takes place twice a year, in the spring and fall, in Guangzhou. The fair attracts more than 25,000 exhibitors and over 200,000 buyers from around the world. While not specific to the pharmaceutical industry, the Canton Fair is a great place to find machinery manufacturers from all over China, including those that produce capsule fillers.

Attending these trade shows can be a valuable way to meet with Chinese capsule filler manufacturers, learn about their products and capabilities, and establish new business relationships. Additionally, these trade shows provide a chance to network with other industry professionals, attend seminars and conferences, and stay up-to-date on the latest trends and technologies in the pharmaceutical machinery industry.

4) Supplyside West and Natural Products Expo West

SupplySide West and Natural Products Expo West are two of the most popular trade shows for finding Chinese capsule filler manufacturers.

SupplySide West is an annual event held in Las Vegas, Nevada that attracts over 17,000 ingredient buyers and suppliers from around the world. The event offers opportunities to learn about the latest ingredient trends, innovative technologies, and market insights. Chinese manufacturers of capsule filling machines often participate in this event to showcase their products and connect with potential buyers.

Natural Products Expo West is another annual event held in Anaheim, California that focuses on the natural and organic products industry. The event brings together over 86,000 industry professionals from around the world and offers opportunities to learn about the latest trends in natural and organic products. Chinese manufacturers of capsule filling machines also participate in this event to showcase their products and connect with potential buyers.

Popular Capsule Filling Machines Used for Filling Hard Capsules

Capsule filling machines come in different types, each with its unique advantages and disadvantages. When selecting a capsule filling machine, it is essential to consider the specific needs of your business and the type of capsules you intend to fill.

1. Main Types of Capsule Filling Machines

There are various types of encapsulation machines available on the market, each with its unique features and advantages. Here are the most common types of capsule filling machines:

1) Manual Capsule Filling Machines

Manual capsule filling machines are perfect for small-scale production or lab use. These low-cost machines have simple structure and are easy to use. Manual machines are operated by hand, and they require the operator to load the empty capsules, fill the powder, and close the capsules manually. They are ideal for filling small quantities of capsules.

2) Semi-Automatic Capsule Filling Machines

Semi-automatic capsule filling machines are suitable for medium-scale production. They are automated to some extent and can fill several hundred to thousands of capsules per hour. Semi-automatic machines can fill both powder and granules and come in various sizes, making them ideal for different production capacities.

3) Automatic Capsule Filling Machines

Automatic capsule filling machines are fully automated and can fill thousands of capsules per hour, making them perfect for large-scale production. These machines have advanced features that ensure accurate dosing, and they can fill both powder and granules. Automatic capsule filling machines come in different sizes and can fill different capsule sizes and types. And generally, automatic capsule filling machines come in two popular types: dosator capsule filling machine and tamping pin capsule filling machine.

2. Advantages of Each Type

Manual, semi-automatic, and automatic capsule filling machines have their own unique advantages and disadvantages.

1) Advantages of Manual Capsule Filling Machines

- Low cost: Manual capsule filling machines are the most cost-effective option for small-scale production.

- Simple operation: Manual capsule fillers are easy to operate, and can be used without extensive training.

- Flexibility: Manual capsule filling machines can fill a wide range of capsule sizes and types.

- Easy to maintain: With fewer parts, manual capsule filling machines are easy to maintain and repair.

2) Advantages of Semi-Automatic Capsule Filling Machines

- Higher production speed: Semi-automatic capsule filling machines can produce capsules at a faster rate than manual capsule fillers, making them suitable for small to medium scale production.

- Accurate dosing: Semi-automatic capsule filling machines have a higher level of precision and accuracy in dosing the capsule fill material.

- Minimal operator intervention: Semi-automatic capsule filling machines require less operator intervention than manual fillers, reducing the likelihood of operator error.

3) Advantages of Automatic Capsule Filling Machines:

- High production speed: Automatic capsule filling machines are the fastest and most efficient of the three types of capsule fillers, making them suitable for large-scale production.

- Consistent dosing: Automatic capsule fillers ensure consistent dosing, reducing the risk of errors.

- Minimal operator intervention: Automatic capsule filling machines require the least amount of operator intervention.

How to Select a Capsule Filling Machine Manufacturer from China

When it comes to importing, it is essential to find reliable and experienced capsule filling machine manufacturers. Here are some factors to consider when choosing a manufacturer:

- Experience in the manufacturing industry

- Production capacity and capability

- Quality control measures

- After-sales support and warranty

- Compliance with international standards and regulations

Below are the suggestions to help you select best Chinese manufacturers:

1. Research and Compare

Start by researching different manufacturers and comparing their products, prices, certifications, and customer reviews. Look for manufacturers who specialize in capsule filling machines and have experience exporting to your country.

2. Check Certifications

Make sure the manufacturer has the necessary certifications for quality control and safety, such as ISO 9001, CE, and FDA. This ensures that their products meet the required standards and regulations.

3. Visit the factory

If possible, visit the manufacturer's factory to inspect their production process and quality control measures. This will give you a better idea of their capabilities and commitment to quality.

4. Request samples

Before placing a large order, request samples of the product to test its quality and performance. This will also give you a chance to evaluate the manufacturer's communication and customer service.

Communicate clearly: Effective communication is crucial in any business transaction. Make sure to clearly communicate your specifications, requirements, and expectations to the manufacturer, and ensure they understand your needs.

5. Negotiate terms

Once you have selected a manufacturer, negotiate the terms of the purchase, including price, delivery time, payment methods, and after-sales service. Make sure all terms are clearly outlined in a written contract.

How to Choose the Best Capsule Filling Machine from China

After identifying a reliable manufacturer, the next step is to choose the best capsule filling machine for your business. Here are some factors to consider:

1. Identifying the Specific Needs of the Business

The type of capsule filling machine you choose will depend on your production volume, the type of capsules you intend to fill, and the level of automation required.

2. Evaluating the Machine's Performance and Efficiency

When evaluating the performance and efficiency of a capsule filling machine, consider factors such as filling accuracy, production speed, and ease of maintenance.

3.Comparing Prices and Warranties

Compare the prices and warranties offered by different manufacturers to get the best value for your money. Look for a manufacturer that offers a comprehensive warranty and after-sales support to ensure that your machine runs smoothly.

4. Best Capsule Filling Machine Recommendation

With their various capsule filling machines, iPharmachine can meet the specific needs of different customer groups. They are confident in providing a one-stop solution for any production requirements.

1) Automatic Capsule Filler NJP-7500

NJP-7500 can produce 7500 capsules per minute, which is up to 450,000 capsules per hour, making it the highest output in the industry. It also features five-stage tamping technology for high-precision powder dosing and a fully enclosed turning table that creates a dust-proof environment.

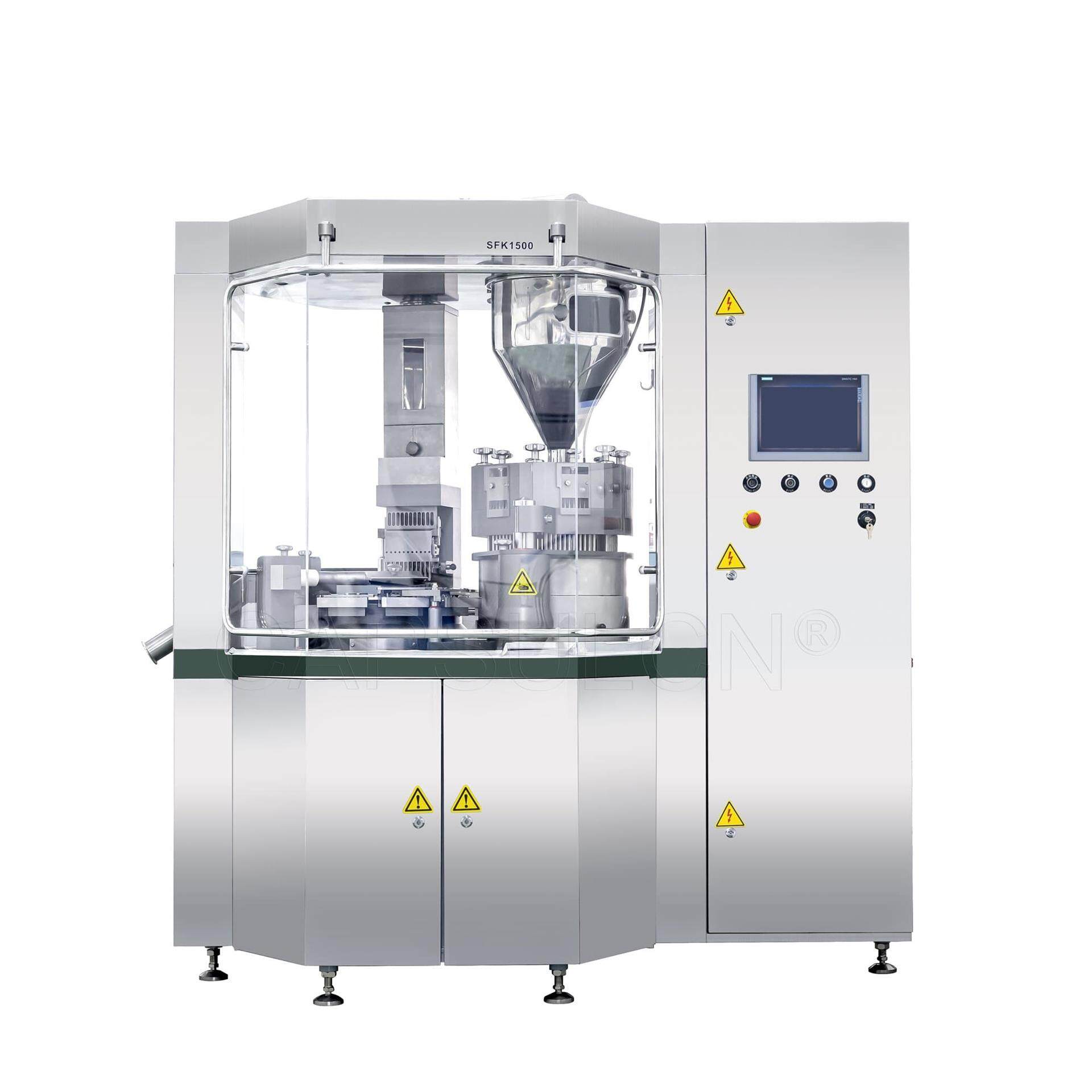

2) Fully-automatic Capsule Filling Machine SFK-3000

The SFK-3000 Fully-automatic Capsule Filling Machine from iPharmachine is a state-of-the-art machine that boasts of several innovative features. One of the most notable features of the SFK-3000 is its use of electrical components of international standards, which ensure a long service life. This means that the machine is built to last and is capable of withstanding years of rigorous use.

Another feature that sets the SFK-3000 apart from other capsule filling machines in the market is its high-precision metering disc filling rod. This technology ensures that each capsule is filled with the exact amount of powder or granules required, thereby minimizing wastage and ensuring accurate dosing.

The SFK-3000 also comes equipped with a Novexx Solutions Motor that operates with low noise and low energy consumption. This makes the machine ideal for use in settings where noise pollution is a concern, and also helps to reduce energy costs.

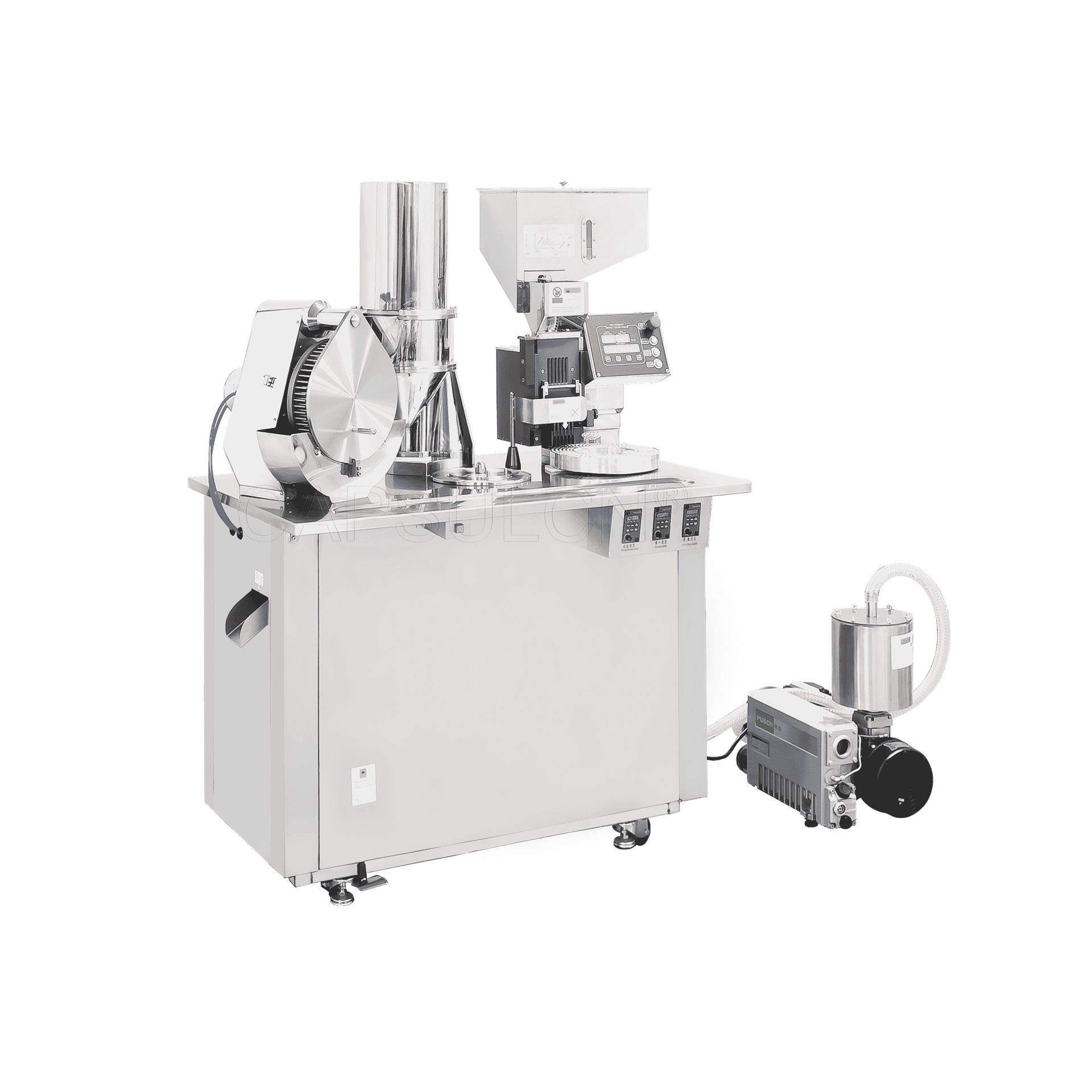

3) JTJ-V Pro+ Semi-auto Capsule Filling Machine

The JTJ-V Pro+ Semi-auto Capsule Filling Machine by iPharmachine is a cost-effective and efficient solution for pharmaceutical companies looking to produce up to 50,000 capsules per hour.

One of the key advantages is its anodized capsule trays. These trays are designed to greatly extend the service life of the machine, ensuring that it can operate at optimal levels for an extended period of time. This feature can result in significant cost savings for manufacturers over the long term.

The JTJ-V Pro+ is also equipped with SIEMENS PLCs, ensuring reliable and consistent performance. These advanced control systems allow for precise dosing of powders and granules into capsules, ensuring accuracy and consistency in every batch.

Common Problems When Importing Capsule Filling Machines from China

When importing capsule filling machines from China, some common problems include:

1. Delays in Delivery

International shipping can be unpredictable, leading to delays in delivery. To mitigate this, it is essential to factor in shipping times and work with a reliable freight forwarder.

To avoid delays in delivery, it is essential to work with a reliable supplier and a reputable freight forwarder who has experience in handling international shipments. You can also factor in shipping times and plan your order well in advance to account for any unforeseen delays.

2. Quality Control Issues

Quality control issues can arise when working with a new manufacturer. It is crucial to verify their credentials and request samples before placing an order.

To avoid quality control issues, it is important to conduct a thorough background check on the manufacturer before placing an order. You can request samples and verify their credentials, such as their business license and quality certifications. Additionally, it's recommended to work with a third-party inspection company to conduct a pre-shipment inspection to ensure that the products meet your quality requirements.

3. Language and Cultural Barriers

Language and cultural barriers can make communication challenging. It is essential to work with a manufacturer that has English-speaking representatives and a clear communication channel.

To overcome language and cultural barriers when working with Chinese capsule filling machine manufacturers, it is essential to establish clear communication channels and work with English-speaking representatives. Utilize translation services or hire a bilingual sourcing agent to bridge the gap in communication. Additionally, take the time to learn about Chinese business culture and customs to establish a positive and productive relationship with your manufacturer.

Conclusion

Importing capsule filling machines from China can be a cost-effective solution for pharmaceutical companies looking to expand their operations. Hopefully, you can find a reliable manufacturer by following the steps outlined in this comprehensive guide, choose the best capsule filling machine for your business, and avoid common problems when importing from China.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche