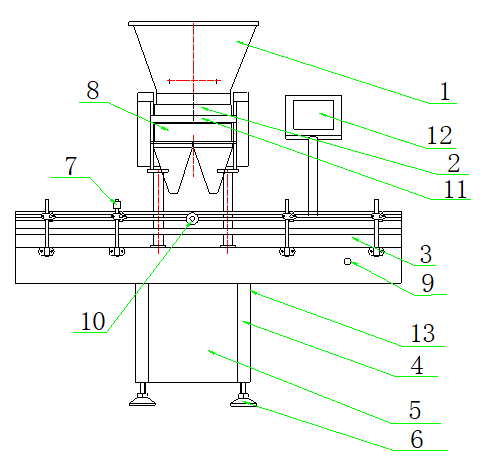

JF-24 Pill Counting Machine: Conponents & Working principle

JF-24 Pill Counting machine figure as follow:

| 1. Inlet hopper | 2. Electromagnetic vibrating plate | 3. Convey track |

| 4. Track support | 5. Mian container | 6. Adjustable foot |

| 7. Photo-electricity eye for seeing bottle | 8.Feeding mouth | 9. Emergency stop |

| 10.Stopper solenoid valve | 11. Photoelectricity inductor | 12.Mirco screen |

| 13. Lift button |

Main components:

1.Mian container: Support the magnetic block of vibration, oscillating trough, hopper and conveyor track. Electrical power distribution system is also installed in the container.

2. Convey track: Delivery the medicine bottles to make the unit work continuously. Switch that can be adjusted is installed in the right inner side. The customer can adjust the speed, according to different requirements to control start and stop of the track. There is an emergency stop knob switch in the outside of track. If unexpected fault happened in the operation, you can press emergency stop button for emergency circumstances. Height of conveyor track can be adjusted to meet the requirements of different bottles. Main adjust point is two main retaining bolt below the track.

3. Electromagnetic vibrating plate: Spread out and separate the particles from the hopper to realize the preparation of counting. There are two groups.

4. Mirco screen: The operation panel is installed in the right of unit case. Set the parameters of the equipment, start and stop, monitor the real time data and check the failure warning.

Working principle

The tablet/capsule counter adopts the principle of photoelectricity induction to count, bottling and delivery the pharmaceutical particles, and monitor and set all operating data in real time. The product is the machine with 24 channels, which means there are 24 vibrated “V”-shaped grooves in the vibrating plate of working table. 8 in left for channel 1 and 8 in right for channel 2, all of them are all respectively to adjust. It make use of vibrating effect to count automatically. The bottles blocking electromagnetic is installed in the track side to ensure that the bottle is stale in filling the medicine. After finishing the setting quantity, Cylinder automatically open, the bottle to be delivered to their transfer conveyor. There is photo-electricity eye for the bottle in the left side of track to detect whether there are empty bottles for the next bottling. If there are no bottles, the vibrator will stop.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche