What are The Different Pharmacy Capsule Machines?

Pharmacy capsule machines are the perfect solution for quick and accurate filling of capsules with various powders, granules, and liquids. Are you curious about the inner workings of pharmacy capsule-filling machines? Do you want to know their advantages and applications? If so, then this blog post is for you.

This blog post will cover everything you need to know about these machines, including their working principles, advantages, applications and uses. We'll discuss the different types of capsule machines available today and what you need to consider before investing in one. By the end of this post, you'll better understand how capsule machines can help you streamline your pharmacy operations. So, let's get started!

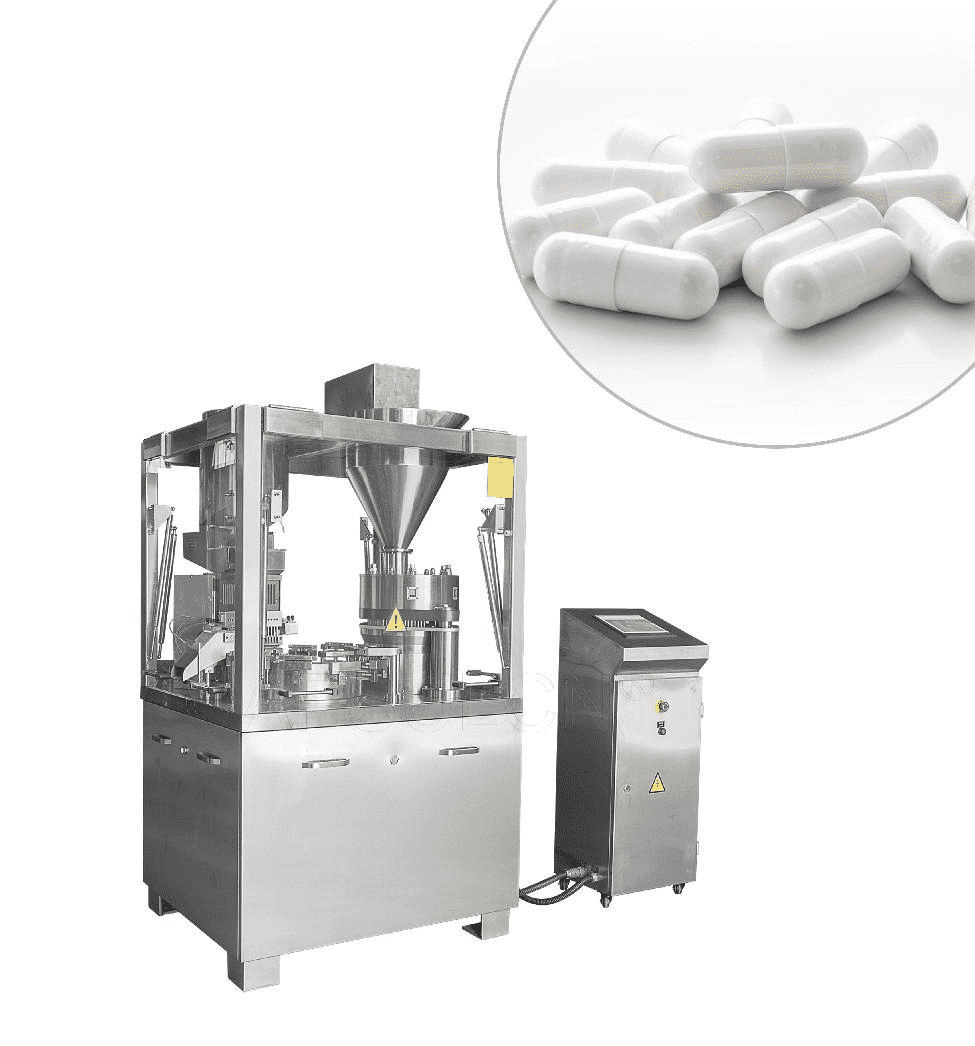

1. Capsule filling machine

Capsule filling machines are pharmaceutical machines that fill powdered or granular products into various sizes of pre-made capsules. The Capsule filling machines have designs that aid in filling capsules accurately and efficiently, thus saving time and cost.

The working principle of the capsule filling machine involves first preparing the capsules by sorting them according to size, weight and shape. Then, the set amount of product is dispensed into the capsules with a filling nozzle. This process's design is quick and accurate to fill the capsules perfectly. Once the capsules are full, the machine seals them to keep the contents fresh and uncontaminated.

1) The advantages of capsule filling machine

- Increased efficiency:

Capsule filling machines increase productivity, allowing for higher quality end products.

- Cost-effectiveness:

The cost of purchasing and maintaining a capsule filling machine is significantly lower than that of manual filling processes.

- Improved safety:

Capsule filling machines are safe to use. Plus they reduce the chances of human error during filling.

- Flexibility:

You can adjust them to accommodate different types of capsules and can even be used for different sizes.

- Reliability:

Capsule filling machines are more reliable than manual filling processes, ensuring consistent product quality with each use.

- Various Application:

The capsule-filling machine is ideal for manufacturing various dosage forms, including powders, granules, tablets, and pellets. It can also be used to encapsulate probiotics and vitamins, which can then be added to various foods and beverages.

- Versatility:

It's also suitable for filling any type of Capsule, such as gelatin, vegetarian, or HPMC capsules.

- Suitable for Various Industry:

In addition to its uses in pharmaceutical production, they are vital in the food industry for filling capsules with various spices, herbs, and other food additives.

2) The applications and uses of capsule filling machine

- The capsule-filling machine is ideal for manufacturing various dosage forms, including powders, granules, tablets, and pellets.

- It's also suitable for filling any type of Capsule, such as gelatin, vegetarian, or HPMC capsules.

- In addition to its uses in pharmaceutical production, they are vital in the food industry for filling capsules with various spices, herbs, and other food additives.

- Capsule filling machines can also be used to encapsulate probiotics and vitamins, which can then be added to various foods and beverages.

2. Hard capsule liquid filling machine

A hard capsule liquid filling machine is an automated machine for filling liquids into hard capsules. This type of machine utilizes several components, such as a hopper, an auger, a piston, and several other parts.

The hopper feeds the liquid material into the machine; the auger transports the material through the device, reaching the filling cylinder. Here, a piston creates pressure to fill the capsules with the set amount of material. Finally, the filled capsules are put out from the machine for further packaging or use.

1) Hard capsule liquid filling machine: application and uses

- For filling capsules with liquid medications, especially in areas where precise and accurate dosings of liquid are needed.

- For various applications, from food and beverage to pharmaceutical and nutraceutical production.

- You can also manufacture various pharmaceuticals such as cough syrup, eyedrops, and antibiotics.

- It's also ideal for producing nutritional supplements such as vitamins, minerals, amino acids, and other supplements.

- They can also fill large batches quickly and efficiently.

- High production capacity and accuracy

- Ability to accommodate a wide range of capsule sizes and shapes

- Automation of the capsule-filling process

- Reduction of labour costs

- High-precision filling and sealing of capsules

2) Advantages of hard capsule liquid filling machine

- High production capacity and accuracy

- Ability to accommodate a wide range of capsule sizes and shapes

- Automation of the capsule-filling process

- Reduction of labour costs

- High-precision filling and sealing of capsules

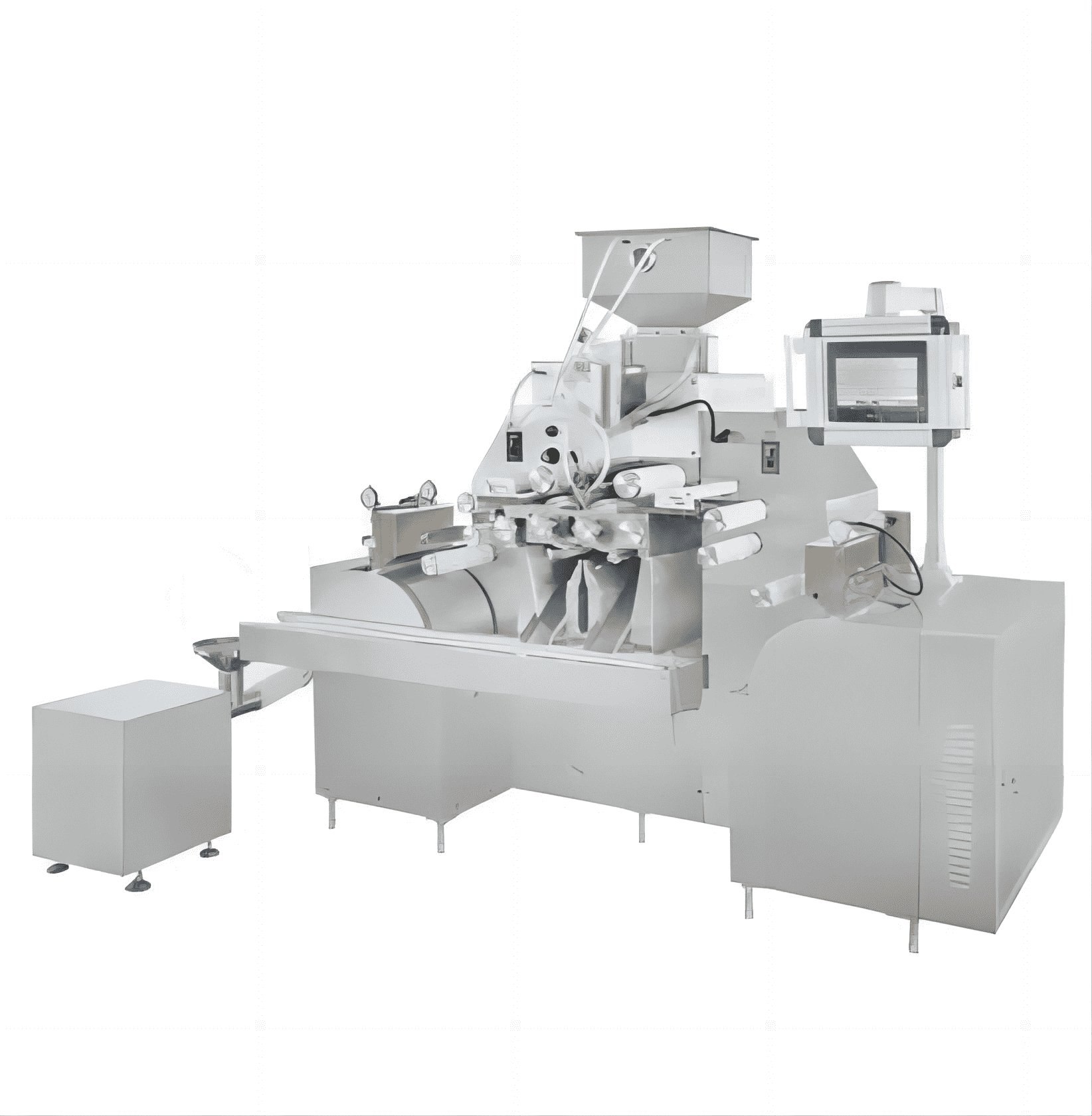

3. Softgel encapsulation machine

The softgel encapsulation process involves several complex steps, beginning with selecting the appropriate gelatin for the softgel capsules. The machine melts the gelatin and then mixes it with oils, fats, or other materials to create the desired filling. After this step, the gelatin is left to cool and solidify before transforming it into individual capsules.

The next step involves loading the liquid, paste, suspension, or ointment into the individual capsules. After that, the individual capsules are put into the softgel encapsulation machine, which is sealed and cut into the desired shape and size. This process ensures each capsule is correctly filled and sealed with the appropriate material. Softgel encapsulation machines are designed to be precise and efficient, ensuring that each capsule is correctly and securely filled with the desired material.

1) Softgel encapsulation machine application and uses

- Softgel encapsulation machines are ideal for encapsulating pills, tablets, and liquid-filled capsules. Plus, you can put many other substances into a soft or hard shell capsule.

- Another application is in the manufacturing of veterinary drugs, nutraceuticals, and other liquid-filled capsules.

- This process is faster and more efficient than traditional hand-filling methods.

- Additionally, these machines can produce a higher quality capsule with greater accuracy than manual methods.

- Softgel encapsulation machines are also used for packaging solid powders and granules.

- Compact design with low noise levels and a small footprint.

- All softgel encapsulation machine parts are easily accessible for cleaning, maintenance, and inspection.

- Optional accessories are available for special applications.

2) Advantages of softgel encapsulation machine

- Compact design with low noise levels and a small footprint.

- All parts are easily accessible for cleaning, maintenance, and inspection.

- Optional accessories are available for special applications.

4. Tablet counting line machine

Tablet counting line machines are more specific equipment for counting and sorting tablets accurately. They work by feeding a line of tablets into a rotating hopper and sorting them into individual pockets.

The basic working principle of tablet counting line machines is quite simple. The machine uses sensors to detect each tablet's size, shape, and color as it passes through its rollers. The machine then sorts the tablets into individual compartments based on these characteristics. It can even recognize various pill shapes and sizes to simultaneously count and dispense multiple pills.

Finally, the tablets are sent out of the machine into the collection bin, ready for further processing or packaging.

1) Tablet counting line machine: the applications and uses

- To count tablets of different shapes, sizes, and weights with great accuracy and speed.

- It's also used for precise counting of tablets for dosage accuracy.

- The tablet counting line machines help reduce the time taken to fill orders, ensuring that all the tablets are accurately counted.

- These machines are often equipped with sophisticated software to easily adjust the number of tablets counted based on the customer's order.

- They also ensure the accurate placement of tablets in the packaging box so they are not damaged.

- High accuracy and repeatability when counting tablets or capsules.

- Easy to use and maintain, resulting in low operational costs.

- Ability to count a large number of tablets or capsules quickly.

- Ability to identify different types and sizes of tablets or capsules accurately.

- Automatically sorts tablets or capsules into pre-determined numbers.

- Can be used for counting capsules for sampling purposes.

2) The advantages of tablet counting line machine

- High accuracy and repeatability when counting tablets or capsules.

- Easy to use and maintain, resulting in low operational costs.

- Ability to count a large number of tablets or capsules quickly.

- Ability to identify different types and sizes of tablets or capsules accurately.

- Automatically sorts tablets or capsules into pre-determined numbers.

- Can be used for counting capsules for sampling purposes.

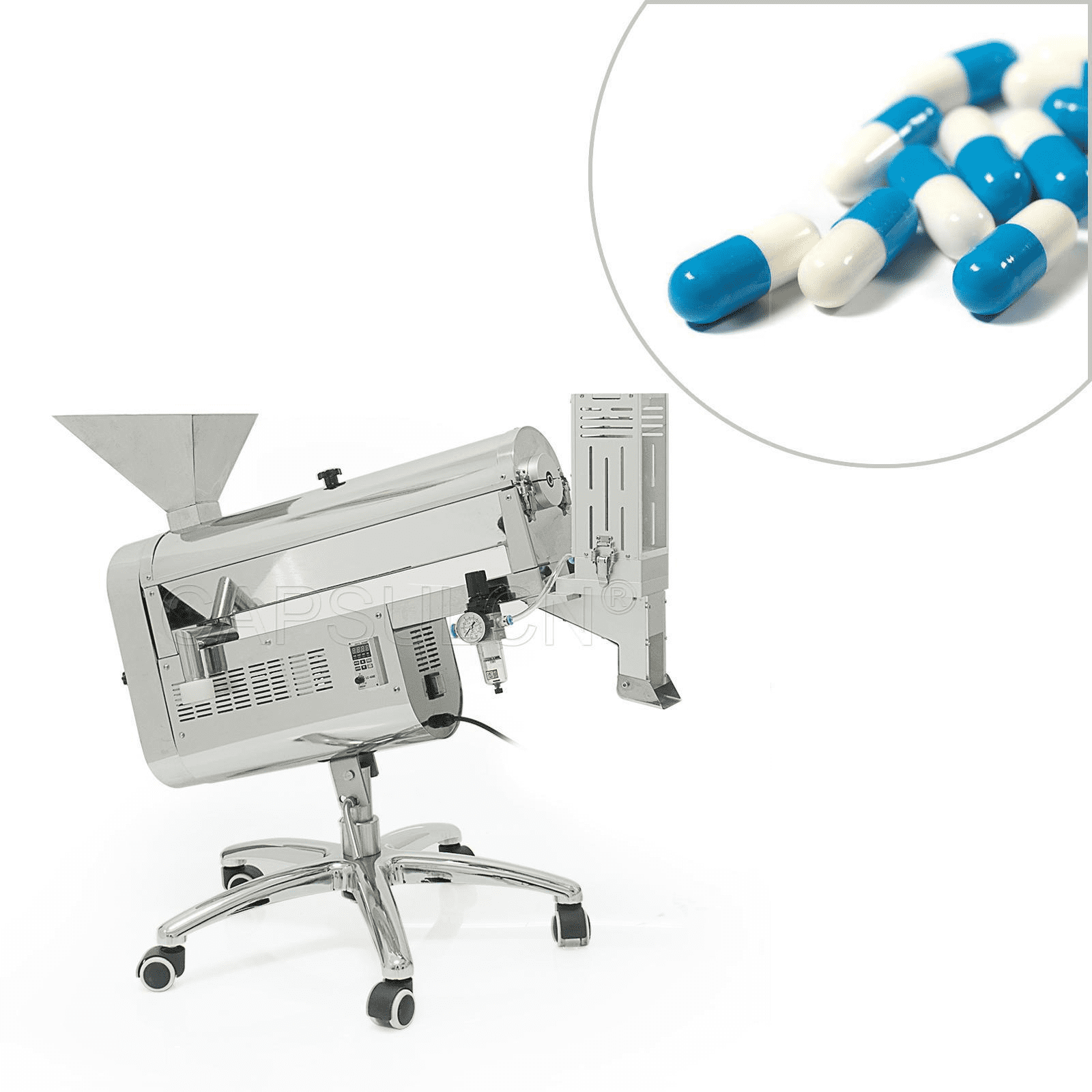

5. Capsule polishing machine

Capsule polishing machines are majorly to polish, clean, and lubricate capsules before filling them. Polishing capsules is essential in filling capsules and maintaining their integrity correctly. The working principle of a capsule polishing machine involves rotating brushes that come into contact with the capsule. Of course, the rotating brushes remove any foreign particles or dirt from the surface of the capsule. Plus, the brushes also apply a thin layer of lubricant to the Capsule, allowing for a smoother operation of the filling machine.

1) The applications and uses of the capsule polishing machine

- Capsule polishing machines are designed to give pills, tablets, and capsules a smooth, glossy finish.

- Manufacturers can create aesthetically pleasing pills with a uniform shape and size.

- The smooth finish also reduces the risk of contaminants such as dust and dirt from collecting on the surface of the pill or Capsule.

- Capsule polishing machines are also used to create capsules with intricate designs.

- Additionally, capsule polishing machines can be used to print text or symbols on the surface of the Capsule to help distinguish it from other products on the market.

- Improved accuracy and consistency of capsule filling

- increased speed and efficiency of production

- reduced risk of contamination; improved shelf life of products; and improved quality of end products.

- Reduction of labor costs and improved workplace safety by reducing manual labor and eliminating the need for dangerous chemicals.

2) Advantages of capsule polishing machines

- Improved accuracy and consistency of capsule filling

- increased speed and efficiency of production

- reduced risk of contamination; improved shelf life of products; and improved quality of end products.

- Reduction of labor costs and improved workplace safety by reducing manual labor and eliminating the need for dangerous chemicals.

6. How to select pharmacy capsule machines

- Consider your budget and the cost of the machines before making a purchase.

- Compare different models of capsule filling machines to determine which one is best for your needs.

- Evaluate the features that each machine has and decide which ones are most important to you.

- Think about how the machine will be used in your pharmacy and if it will require any additional accessories or parts.

- Make sure that the machine is compatible with your current setup and meets all safety standards.

- Check the customer reviews to get a better understanding of how the machine performs in real-life scenarios.

- Ask for recommendations from other pharmacists or those who have already purchased a similar machine.

- Research the manufacturer and make sure they have a good reputation.

7. Top 5 capsule filling machine manufacturers

As capsule filling machines is the critical equipment in the capsule manufacturing process, it is important to pick the the top-rated capsule filling machine manufacturers that suit you most. Below are the top 5 capsule filling machine suppliers for your choice:

1) iPharMachine

iPharMachine is a company based in China that is considered one of the best pharmaceutical machinery manufacturers in the country. They offer a wide range of capsule machines, including manual capsule fillers, semi-automatic capsule filling machines, and fully automatic capsule filling machines like the NJP series and SFK series.

In addition to capsule machines, iPharMachine also offers other pharmaceutical equipment such as tablet presses, blister packaging machines, and capping machines. The company is also a leading supplier of empty capsules and capsule-filling equipment worldwide.

2) Cadmach Machinery Company Ltd.

Cadmach is a leading manufacturer of fully automated capsule filling machines that provide fast and efficient production. Their machines are designed with safety and precision in mind and can handle a variety of different capsules sizes and shapes. They also offer a range of customization options to help you create the perfect machine for your pharmacy.

3) Fette Compacting GmbH

Fette is a renowned name in the industry and their capsule filling machines are widely used by pharmacies around the world. Their machines are available in various sizes and feature advanced technology that ensures precise and accurate performance. Plus, they offer high-speed production capabilities and can handle a variety of capsule sizes and shapes.

4) Bosch Packaging Technology

Bosch offers a wide range of capsule filling machines that are highly efficient and reliable. Their machines feature intuitive software that allows you to quickly adjust settings to accommodate your needs. Plus, they offer a selection of special features, such as user-friendly interfaces and efficient operation.

5) Korsch AG

![]()

Korsch specializes in manufacturing automated capsule filling machines that are easy to use, highly efficient, and cost-effective. Their machines provide exceptional performance and come with a variety of features, such as flexible settings, high-quality materials, and quick changeover times. Plus, they offer a wide range of customization options for those who need specialized solutions.

8. To wrap it up

Capsule machines are an essential piece of equipment for any pharmacy. They provide a fast and efficient way to fill capsules quickly and accurately and reduce the amount of human labour needed to fill orders. These machines can be used for various applications, including pill counting, capsule polishing, and capsule filling.

Using capsule machines can increase efficiency and accuracy in the pharmacy and decrease the overall time needed to fill orders. With a suitable capsule machine, pharmacists can ensure their customers receive the correct dosage and type of medication without any mistakes or delays.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche