Top 10 Capsule Filling Machine Suppliers (2024 Reviews)

Are you looking for best capsule filling machines for your pharmaceutical business? Then you should find professional capsule filling machine suppliers. As we know, the capsule filling process is sophisticated.

Advanced capsule fillers can automatically complete loading, separating, filling and capping. They tend to consist of parts like PLC, automatic loading devices, powder dosage filling devices, etc.

Only top-notch capsule fillers can produce capsules efficiently - let's say you want to produce over 10k capsules per hour. On top of that, they can achieve accurate dosing, low powder waste, and conform to the hygiene requirements of cGMP.

Thus, instead of start-ups, you surely want to source them from reputable suppliers. To help you find your partners, this blog has listed some top suppliers in the world.

Read more: What is Capsule Filling Machine: A Quick Overview

1.Top 10 capsule filling machine suppliers in the world

Syntegon

-

Company Introduction

If you ask who is the best capsule filling machine supplier, this may be a hard question to answer. But Syntegon, with its 160 years of experience in the pharmaceutical industry and over 50 years of experience as a capsule filler supplier, can no doubt claim to be one of the leading companies.

In 2020, Bosch Packaging Technology left Bosch Group and was renamed Syntegon. And today, to better serve their wide range of customers, they have set up subsidiaries in more than 30 locations worldwide.

Every day, their 5,800 employees pursue a common goal, "processing and packaging for a better life". They are detail-oriented to improve people's lives and always provide top-notch machines.

-

Product Highlights

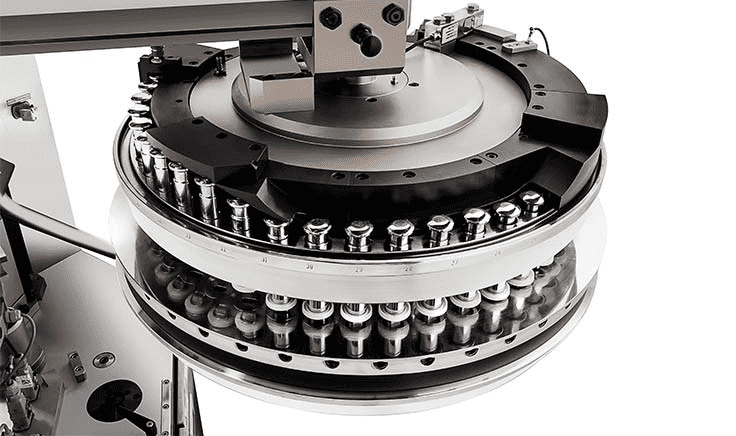

Regarding capsule fillers, their GKF series is well suited for all kinds of applications. Whether small-scale production like R&D, medium-size production like a pilot-scale experiment, or large-scale manufacturing, Syntegon can never fail to meet your expectations.

For different filling materials, they always adopt proper technology. They have mastered slide-gate technology for powder/pellets filling, vacuum-wheel dosing for micro-dosing capsules, and precise volumetric dosing for liquid filling.

As for safety, their GKF Containment series has the feature of barrier systems. This system can separate the operators from the product area, reducing the exposure to harmful ingredients. As for the features of ProTect and HiProTech, they can well ensure personal safety even at the OEB 4 or OEB 5 level.

Their product ranges include:

- GKF Performance series

- GKF Selection series

- GKF Containment series

- GKF Capsylon series

iPharMachine

-

Company Introduction

In recent years, Chinese pharmaceutical processing & packaging industries have been developing rapidly. Now, China is the second largest manufacturing region - second only to Europe.

Among many Chinese counterparts, iPharmachine can claim to be a real expert. Well, their great skills speak for themselves:

At first, a company named CapsuleCN started with manual encapsulators. They only serve small pharmaceutical companies. Growing together with their partners, they gradually become the industry's pioneer in China.

Due to the strict material selection and delicate craftsmanship, the manual encapsulator series has become a real hit. You will find their CN series if you have searched on major e-commerce sites or Google. Their iconic acrylic sheets are so eye-catching that you will love them at first sight.

During nearly 20 years of development, CapsuleCN International always craft the best capsule filling machines. And many of them become return customers when they have grown into a successful businesses.

But CapsulCN was not pleased with themselves and continued to pursue the ultimate level of craftsmanship. In 2013, they established a subsidiary brand iPharmachine, providing professional pharmaceutical processing & packaging solutions.

To keep machines up-to-date, their engineers work tirelessly to innovate in expertise. They combined German technology with Chinese manufacturing advantages. And finally, they successfully brought about many revolutionary products.

Today, they are capable of providing all kinds of pharmaceutical packaging machines. Their business ranges from raw material processing, capsule filling, and tablet pressing to powder & granule packaging and bottle filling. iPharmachine has the confidence to provide a one-stop solution for any production requirements.

-

Product Highlights:

The biggest highlight of iPharmachine's capsule filler is the diverse product lines:

From Semi-automatic Capsule Filler JTJ-V Pro+ (cost-effective yet powerful), Automatic Capsule Filler NJP-7500 (450,000 capsules per hour), to Full-automatic Capsule Filler SFK-3000 (features the most advanced technology in the industry), iPharmachine can satisfy the various needs of different customer groups.

The features of the JTJ-V Pro+ Semi-auto Capsule Filling Machine:

- Cost-effective yet efficient (50,000 capsules per hour, close to the output of the fully automatic filler NJP-800)

- Anodized capsule trays can greatly extend the service life

- SIEMENS PLCs

The features of Automatic Capsule Filler NJP-7500:

- Capable of producing 7500 capsules per minute (up to 450,000 capsules per hour, the highest output in the industry)

- 5-stage tamping technology for high-precision powder dosing

- Fully enclosed turning table creates a dust-proof environment

The features of the Fully-automatic Capsule Filling Machine SFK-3000:

- Electrical components of international standard which ensures the long service life

- High-precision metering disc filling rod

- Novexx Solutions Motor with low noise and low energy consumption

Fette Compacting

-

Company Introduction

In 1948, Fette Compacting invented its first tablet press and started setting industry standards. As one of the pioneers in the industry, they have been dedicated to tablet compressing technology for over 70 years. And today, they can claim to be a real leader in tablet production.

On top of the cutting-edge technology, Fette Compacting is also renowned for its comprehensive service. Globally, they have 800 service employees. They are available for comprehensive services in different regions.

Their services include technical support, maintenance, and replacement of spare parts and equipment. Leave all your problems for Fette Compacting. They will keep your machines up-to-date.

-

Product Highlights

In 2016, Fette Compacting launched its first capsule filler, FEC40, at the Interphex in New York. The biggest highlight of their encapsulators is "efficiency".

Boasting a smart interface, modular design and the high-precision NMC (Net Mass Control) sensor, the FEC Series can achieve great performance with low waste.

So if you're sourcing capsule fillers for medium or large-scale production, then the FEC Series can be your best bet. It can fulfil your needs with its top-tier quality and high performance.

The Features of FEC Series:

- HMI (Human Machine Interface) for intuitive operation

- Flexible set-up for saving time

- Easy-to-dismantle stations for faster changeover and cleaning

- High production capacity (up to 20k to 40k capsules per hour)

Capsugel

-

Company Introduction

Founded in the 1960s, Capsugel is a leader in hard capsule manufacturing. With their expertise in capsules and the equipment for pharmaceutical R&D, they now have more than 5000 customers in over 100 countries.

In capsule manufacturing, they always lead the market with unsurpassed productivity. They have 4 innovation labs and 12 manufacturing sites. That accounts for their capacity of manufacturing 230 billion capsules every year.

Regarding capsule filling machines, Cpsugel has its strengths as well. They specialize in the equipment for R&D, clinical batches and medium-size production.

-

Product Highlights

Are you looking for equipment for early-phase product development or medium-size production? Then Capsulgel may be your ideal choice. Not only because they have mastered encapsulation technologies but also because they have the drug development know-how.

Their featured products include cGMP-compliant Ultra III Semi-automatic Capsule Fillers and Micro-dosing Systems. All these patented products have features that support your R&D requirement.

Further, Capsugel offers considerate services to help your early phase clinical programs. Their support services include micro-dosing, packaging, distribution, and return services.

Their micro-dosing systems include:

- Xcelolab for lab-scale

- Xcelodose 120S: semi-automated

- Xcelodose 600S: fully automated

ACG Group

-

Company Introduction

Founded in Mumbai in 1961, ACG has always served pharmaceutical and nutraceutical companies. It has become a multinational company with its presence in 138 countries on 6 continents.

Today, they can produce up to 120 billion capsules every year. Ad they have installed 23,947 machines for customers around the world.

As a member of the pharmaceutical industry, they know they have the responsibility to take machines seriously. Because they know pharmaceutical equipment is all about saving lives.

From innovative design to the most stringent quality control, ACG takes every detail seriously. And now, they take the initiative to cooperate with global experts.

In 2016, ACG acquired its German process development team. In February 2021, ACG set up its process development laboratory.

And then, they invited their global customers to participate in the development. Up to now, ACG is also collaborating with equipment designers from all over the world.

If you are looking for suppliers from India, then ACG can best suit your needs.

-

Product Highlights

Due to the large investment in R&D, ACG has mastered many core technologies. And they can ensure the superior performance of their equipment.

For instance, they have acquired the patent named ZRO technology. With the aid of it, the ZRO series can encapsulate a wide range of complex formulations. Further, they have adopted the dostar technology, which has achieved accurate micro-dosing (up to 15mg).

The features of the AF series:

- Capable of encapsulating wide ranges of complex formulations.

- Flexible to fill capsules with various combinations, such as powder, tablets, micro- tablets, pellets, softgel and the capsule in a capsule combination

- Adopt precise slug dosing technology, which ensures high precision

- Able to integrate with Accura - their self-developed capsule checkweigher

Harro Hofliger

-

Company Introduction

When it comes to choosing the best supplier of capsule filling machines, Harro Hofliger is a name that stands out in the pharmaceutical industry. With over 50 years of experience in designing and manufacturing innovative solutions for filling and packaging, Harro Hofliger has established itself as a leader in the field.

Founded in 1975, Harro Hofliger has grown into a global company with over 1,400 employees in more than 20 countries. Their team of experts is dedicated to developing cutting-edge solutions that meet the ever-evolving needs of the pharmaceutical industry.

The capsule filling machines manufactured by Harro Hofliger are intended to produce high-quality goods that are up to the standards set by the industry. Their equipment is fitted with cutting-edge technology, and it has a user interface that is intuitive and straightforward, so it can be applied to production on any scale, from the smallest to the largest. The accuracy and effectiveness of the machines manufactured by the business contribute to a reduction in the overall cost of production.

-

Product Highlights

Harro Hofliger offers a wide range of capsule filling machines that are designed to meet the needs of different production levels.

The Modu-C MS series is ideal for small to medium-scale production, with a capacity of up to 200,000 capsules per hour. It features an easy-to-use touchscreen interface and precision dosing technology for accurate filling of powders, pellets, and granules.

Their other products include:

- Modu-C MS series

- Modu-C MS CF series

- Modu-C MS Twin series

- Modu-C MS Micro series

ROMACO

-

Company Introduction

Romaco, with over 40 years of experience as a leading manufacturer of pharmaceutical machinery, is a company that has made a name for itself in the industry.

Founded in 1991, ROMACO has been providing high-quality machinery to the pharmaceutical, food, and chemical industries for decades. The company is headquartered in Karlsruhe, Germany, and has subsidiaries in over 10 countries around the world. ROMACO's focus is on providing solutions for processing, dosing, and packaging, with a particular emphasis on capsule filling machines.

-

Product Highlights

ROMACO provides its customers with a diverse selection of capsule filling equipment, including the following:

A highly developed and automated capsule filling machine, the Macofar MT Series is capable of filling up to 200,000 capsules per hour.

Macofar CD Series is a capsule filling generator that is semi-automatic and has the capacity to fill up to 40,000 capsules per hour.

Other Product Ranges include:

- Macofar E

- Unity 300 blister

- KTP 1X

- TP R Optima

PTK-GB Limited

-

Company Introduction

PTK-GB Limited is a UK-based company that majors in the design, manufacture, and supply of capsule filling machines. The company's dedication to quality and customer service has made it one of the leading capsule filling machine suppliers in the world.

The capsule filling machines produced by PTK-GB are well-known for their high levels of productivity, dependability, and flexibility. They are developed to cater to the particular requirements of the pharmaceutical business, which guarantees that they are of the highest possible quality and comply with all applicable safety regulations.

-

Product Highlights

PTK-GB Limited offers a wide range of capsule filling machines that are suitable for various applications.

The company's capsule filling machines are equipped with advanced technology to ensure accurate and efficient filling. They use a range of filling technologies, including slide-gate technology for powder/pellets filling, vacuum-wheel dosing for micro-dosing capsules, and precise volumetric dosing for liquid filling.

Safety is also a top priority at PTK-GB Limited. Their capsule filling machines are designed with advanced safety features, including containment systems to protect operators from exposure to harmful ingredients. Their machines also feature advanced technologies like ProTect and HiProTech, which ensure personal safety even at the OEB 4 or OEB 5 level.

-

Product Ranges

PTK-GB Limited produces many of capsule filling machines that include the following series:

- • PTK-FS series: This series is ideal for small-scale production, laboratory testing, and R&D applications.

- • PTK-SL series: This series is ideal for pilot-scale experiments and small-scale production.

- • PTK-PL series: This series is ideal for medium-scale production and pilot-scale experiments.

- • PTK-HP series: This series is ideal for large-scale production and offers high-speed and high-efficiency filling.

- • PTK-CV series: This series is ideal for high-precision filling of liquids.

DOTT. BONAPACE & C.

-

Company Introduction

DOTT. BONAPACE & C.,a company with more than 70 years of experience in the pharmaceutical industry, can undoubtedly be considered one of the top capsule filling manufacturers.

Founded in 1946 in Naples, Italy, DOTT. BONAPACE & C. has grown to be a leading supplier of capsule filling machines, counting over 5,000 customers worldwide. The company is known for its innovative solutions, high-quality machines, and exceptional customer service.

-

Product Highlights

DOTT. BONAPACE & C. offers a wide range of capsule filling machines that cater to all types of applications. Their range of capsule fillers includes semi-automatic and fully automatic machines, suitable for small to large-scale production.

One of their most popular machines is the VEGA Series, which features the latest technology in capsule filling. The VEGA series is designed to handle different capsule sizes and can produce up to 400,000 capsules per hour, making it ideal for large-scale production. The machine also features advanced electronic systems for precise dosing and filling.

DOTT. BONAPACE & C. also offers the LILIPUT Series, which is designed for small-scale production and laboratory use. This machine is suitable for filling powders, pellets, and granules and can handle a wide range of capsule sizes.

-

Product Ranges

DOTT. BONAPACE & C. offers a wide range of capsule filling machines, including:

- VEGA Series

- LILIPUT Series

- PICCOLA Series

- MINIMA Series

- SOFTGEL Series

I Holland

-

Company Introduction

I Holland is a leading manufacturer of tablet tooling and pharmaceutical machinery, with over 70 years of experience in the industry. Founded in the United Kingdom in 1947, I Holland has established a strong reputation for innovation, quality, and customer service.

Based in the UK, I Holland specializes in manufacturing tablet tooling and capsule fillers, providing cutting-edge solutions to meet the demands of modern pharmaceutical manufacturing.

-

Product Highlights

CFM Series - a precision capsule filling machine that features an automated weight control system, an electronic capsule size selection system, and a user-friendly touchscreen interface.

CAPplus - an advanced system designed to increase the efficiency of capsule filling by up to 25%, using advanced software to optimize the filling process and ensure consistent, high-quality results.

-

Product Range

Holland offers a range of capsule fillers to meet the varying needs of their customers. Their product range includes:

- The CFM series for high-speed production of capsules

- The Semi-Automatic series for smaller-scale production

- The Auto Tab for the automated filling of tablets

- The PF-1 for the semi-automatic filling of powders

- The TAB-IT for the automated filling of tablets

2.What types of machines do capsule filler manufacturers offer?

Generally speaking, three main types of encapsulators are available in the market. And they have different degrees of automation. They can be divided into manual capsule fillers, semi-automatic capsule fillers, and automatic types.

Manual capsule fillers are the most cost-effective option for buyers. You only need to spend around $100 to $3000 to purchase one, which can help you produce 600 to 4000 capsules per hour.

As for semi-automatic types, they have achieved a relatively high level of automation. But it still needs extra personnel to complete some operations. For instance, they still need operators to put together upper and lower capsule trays.

Their costs are around $10k to $25k, and they can produce up to 10k to 20k capsules per hour. For medium-size production, semi-automatic encapsulation machines can be your ideal choice.

For commercial production, automatic capsule fillers are the most efficient type. Despite their high initial cost, they will most likely skyrocket your business in the long run. The reasons are self-evident. It can help you save human labour, as a PLC and a mechanical drive system can help you finish most of the operations.

In general, the cost of automatic capsule fillers is between $30k to $50k or even higher. And its production capacity can reach 12k to 450k capsules per hour.

According to MarketWatch, 80 per cent of capsule filling machines are automatic types. In contrast, semi-automatic capsule fillers only account for only 13 per cent.

3.Market Insights and the main regions of capsule filling machine suppliers

According to Future Market Insights, the global market size of capsule fillers will increase from around $561.4 million in 2022 to $894.4 million in 2032. Among all the competitors, Europe accounts for 44 per cent of the market share. This region has many most senior capsule filling machine suppliers. They have the longest manufacturing history and state-of-the-art equipment.

China is the second largest region, which accounts for 20 per cent of the market share. Despite the short history, companies in this region have been developing rapidly in recent years.

Many of them can provide customized equipment and complete production lines. North America is the third largest region, accounting for 9.9 per cent of the global market. Then comes the fourth one, India, which accounts for 9.7 per cent.

4. Conclusion

The capsule filling machine suppliers listed above are the top-rated suppliers worldwide. Generally, suppliers from Europe, China, North America and India have rich experiences. Capsule filler suppliers from Europe tend to boast the longest manufacturing history. They can provide you with state-of-art equipment.

And with years of development, Chinese and Indian suppliers are no worse than their European counterparts. They can offer you top-notch machines as well as one-stop solutions as well. As for what are the best encapsulators, it may be a hard question to answer. Since these top capsule filling machine suppliers have different strengths. And they suit different buyers. Make sense of your brand position, and cooperate with a reliable supplier. Then, you will gain a lot in the long run.

Read more:

Top 5 Softgel Encapsulation Machine Manufacturers Worldwide

Top 5 Semi-Automatic Capsule Filling Machine Manufacturers Worldwide

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche