What is Capsule Filling Machine: A Quick Overview

Are you looking for detailed information on capsule filling machine? This article will give you a quick overview of what is capsule filling machine. And if you have the patience to finish reading, you will know the capsule filling machine definition, their types, and how do their work.

1. What is capsule filling machine?

/manual-capsule-filling-machine-cn400l.jpg)

/semi-auto-jtj-v-pro.jpg)

/njp-2000c.jpg)

What is capsule filling machine? Capsule filling machine is also called capsule filler, encapsulator or encapsulation machine, a sort of pharmaceutical processing equipment used for filling empty capsules. And the substances they fill include powder, pellets, tablets, granules, liquids, or different combinations, which contain active pharmaceutical ingredients (APIs). The whole filling process is known as encapsulation.

2. What are the different methods of filling capsules?

After learning what an encapsulation machine is, you must have a clear view of the capsule filling machine's definition. And now, let's jump on their types of capsule filling machine.

1) A quick overview of different types of capsule fillers

According to the degree of automation, there are three types of encapsulators:

- Manual capsule filling machine

- Semi-automatic capsule filling machine

- Hard gelatin automatic capsule filling machine

- Liquid capsule filling machine (automatic)

And the hard gelatin automatic capsule filling machine can be divided into two main types:

2) The differences between these capsule fillers

The major difference among these types of capsule fillers is the output. Generally speaking, a manual capsule filler can only fill 600 to 4000 capsules per hour. While in comparison, a semi-automatic capsule filling machine can fill 10,000 to 20,000 capsules per hour. And the filling capacity of automatic ones ranges from 12,000 to 450,000 capsules per hour.

As for the applications of the encapsulation machine, manual capsule fillers can meet the needs of family use or small-scale production. And semi and fully automatic capsule fillers, due to the features like PLCs and mechanical drive systems, are widely used for pilot production or medium and large-scale manufacturing.

On top of that, due to the complexity of their mechanism, the costs of these capsule fillers are also different. A manual machine is the most cost-effective one, which only costs you 10 to 3,000 dollars on average. In comparison, a semi or automatic one is much more expensive. On average, their prices are 10k to 25k dollars and 30k to 50k dollars separately.

3. The working principle of the capsule filling machine

As mentioned above, there are three main types of capsule filling machines. Obviously, because they have distinct parts, the principle of the capsule filling machine is different.

On the other hand, the capsule filling process has something in common. These processes include: the orientation of capsules, separation of caps and bodies, filling up the capsule body, rejoining caps and body, and the ejection of capsules.

To have a clear view of what is capsule filling machine below is a brief introduction to its working principle. And since the automatic capsule filer has the most complex structure, we'll take the principle of the automatic capsule filling machine as an example.

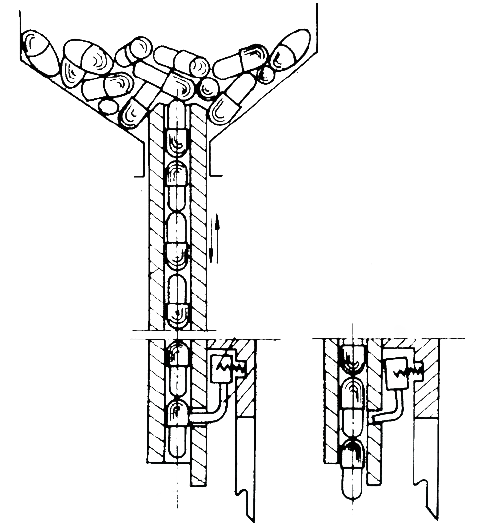

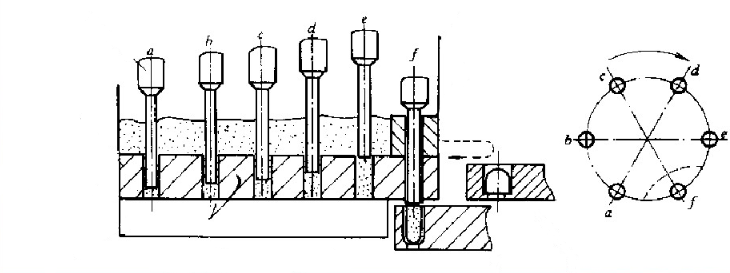

1) Rectification (Orientation)

In this process, joined capsules are randomly poured into the delivery plate and fall in front of the horizontal and vertical forks. At this time, the capsules have either a body end downward or a cap end downwards.

Then the direction of the capsules will be adjusted by the push of horizontal and vertical forks. With the aid of forks, capsules are always bent downward when entering the segment.

/capsule-rectification.jpg)

2) Separation of caps and bodies

After rectification, the capsule tray will load capsules with their body downward. One thing to note: The loading amount depends on the holes of the capsule tray. The holes determine the number of capsules that can be filled per time.

After the capsule tray transfers the capsules to the separation station, they will be separated by the vacuum system. Then the upper and lower parts of the capsule tray will be transferred to different stations separately.

/capsule-separation.jpg)

3) Capsule filling

After separation, the body will be transferred to the filling station. Capsule filling is the most important part of the whole procedure. Generally speaking, there are two main types of filling methods that are commonly seen - the tamping pin filling and the dosator capsule filling.

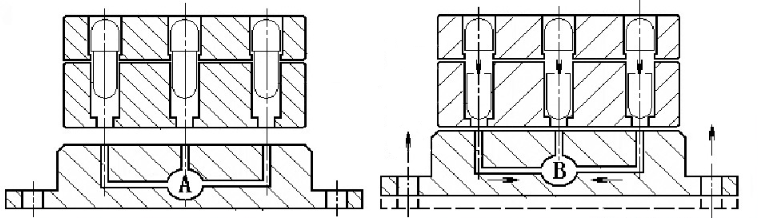

- Tamping pin capsule filling

Tamping pin filling is widely used in automatic capsule filling machines. It has a dosing disc with several holes. As the powder flows into the holes, the tamping pin (or tamping punch) compacts the powder.

After finishing the compression, the dosing disc will rotate and transfer the powder to the next tamping pin for compressing. Meanwhile, the powder will automatically flow into the dosing disc holes.

When the hole is filled up with compressed powder (after the compression of 5 pins), the powder will be filled into the capsule body.

The main advantages of tamping pin capsule filling machines are their high working efficiency and great accuracy.

/capsule-filling-station.jpg)

- Dosator capsule filling

Unlike tamping pin capsule fillers, dosator capsule filling machines only rely on one dosator and one small pin to fill empty capsules.

The dosator process is very simple. During the filling process, the dosator will be inserted into the powder bed. And when the powder enters the cavity of the dosator, the small pin in the dosator system will compact the powder to form a slug. And then, the dosator will inject the slug into the capsule.

Compared with tamping pin capsule filling machines, a dosator type machine may not be that efficient, but it can achieve micro-dosing of capsules. Normally, micro-dosing refers to filling capsules with a very small amount of powders.

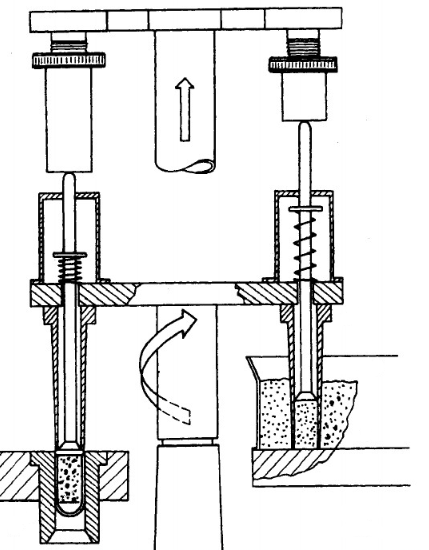

4) Capsule locking and ejection

After filling, the upper and lower capsule trays overlap again in the locking station. At this time, the force from the up baffle plate and the lower pin locks together the caps and the bodies.

At last, with the aid of compressed air, the capsule ejection device is responsible for ejecting capsules into the outlet.

/capsule-ejection.png)

4. The bottom line

Actually, the capsule filling machine plays a key role in pharmaceutical processing. Thus, it would help if you have a deep understanding of what is capsule filling machine and how they work.

The last thing you want to note is that if you want to find the best encapsulators for commercial use, you need to partner with a top-rated capsule filling machine supplier. They can offer you a one-stop solution and worry-free services. In the long run, they are the ones who are likely to boost your business.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche