Types of Tablet Coating Machines: The Ultimate Guide

Tablets are one of the most popular solid oral dosage forms manufactured in the pharmaceutical and nutraceutical industries. If you're running a pharma or supplements company, you must be no stranger to one of the pharmaceutical processes - tablet coating. And it can be split into three common types: sugar coating, film coating and enteric coating.

As you surely know, tablet coating is a straightforward process. It applies a non-sticky, thin layer of coating material to the surface of the tablets. This pharmaceutical technique enhances the benefits of the solid dosage form while improving the patient and consumer experience.

Yet, if you're looking to consistently produce defect-free tablets with a uniform coating, you need top-notch devices. In this article, you can get deeper insights into different types of coating equipment that you can purchase from a tablet coating machine supplier.

Different types of tablet coating machines

So What is a tablet coating machine? Tablet coater is designed to automatically perform the process of placing a thin layer of safe ingredients around the external surface of tablets. Today, the tablet coating machines available in the market can be classified into three types.

1. Standard coating pan

A standard coating pan is a conventional type consisting of a circular metal pan tilted at an angle of 30-45 degrees on a stand. The diameter of the coating pan can be in the range of 15-200 cm.

After the tablets are loaded, the pan starts to rotate, driven by an electric motor. The rotation enables the tablets to tumble and get coated with the premixed solution.

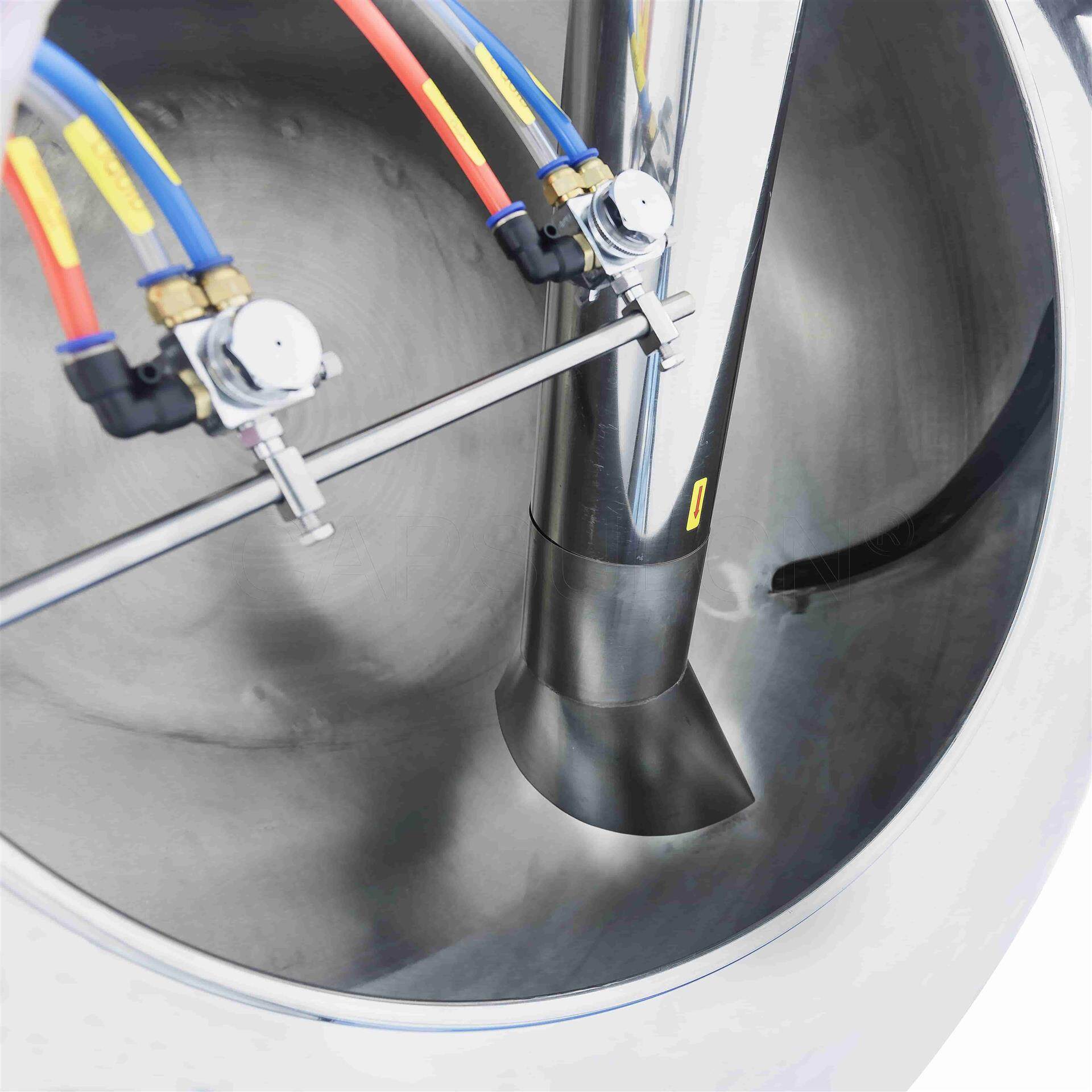

This conventional coating pan features an air-atomized spray system that evenly distributes the coating material to every single tablet. In the meantime, heated air is supplied through a built-in hot air blowing system to dry the coating solution. And the heated air exits through the exhaust in the front of the pan.

To improve the coating drying efficiency, the standard coating pan typically employs three types of systems.

a. Pellegrini pan system: This system comes with a diffuser and a baffled pan. The design helps distribute heated air evenly through the tablet bed. It should be mentioned that the Pellegrini pan is only suitable for the sugar coating process but not for film coating due to limitations in its drying capability.

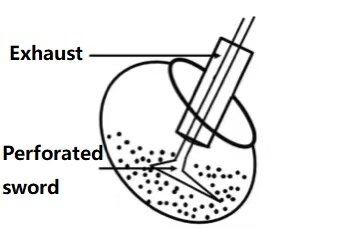

b. Immersion sword system:This system uses a perforated metal sword immersed in the tablet bed to let the drying air in. The immersion sword system helps create a more efficient drying environment by allowing the heated air to be blended seamlessly with the liquid coating around the tablets.

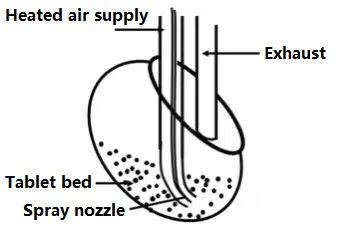

c. Immersion tube system: This system is designed with a tube that can be immersed in the tablet bed. The tube comes with a spray nozzle at the tip to deliver the heated air for drying. During this process, the coating solution is supplied simultaneously with the heated air from the tube.

At iPharMachine, we offer a broad selection of standard coating pans. The BYC series tablet coating machine can give an output of up to 80-150kg/cycle while ensuring perfect coating results.

2. Perforated pan

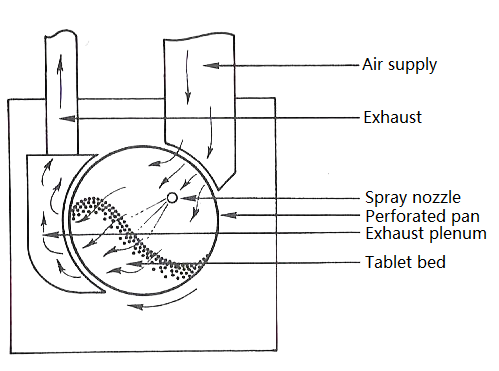

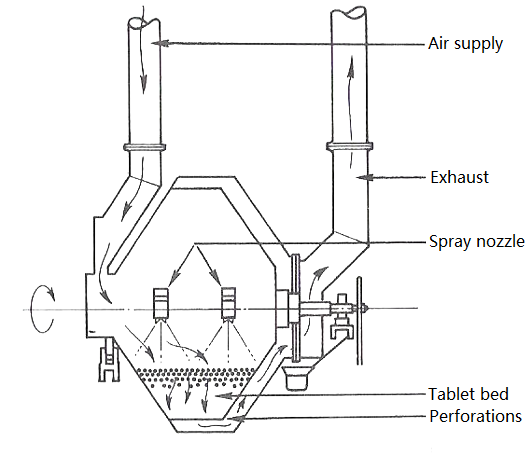

A perforated pan is one of the most efficient types of tablet coating machines. This device is designed with either a partially or fully perforated drum. The drum works to coat tablets by spinning on a horizontal axis in an enclosed housing. The perforated pan uses spraying nozzles to evenly apply coating solution to the surface of the rotating tablet bed.

The wholly enclosed system is fabricated with manifold spray guns inside the drum for the distribution of coating solutions. This system provides a more efficient drying method and higher coating capacity than other coating systems. It can be fully automated for both sugar coating and film coating processes.

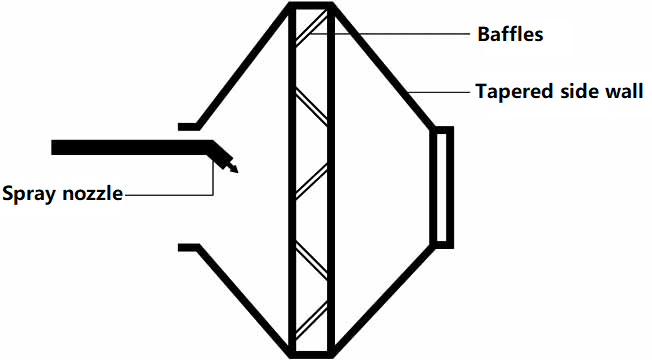

The perforated pan systems also come in a variety of designs to maximize drying efficiency.

a. Accela-cota is one of the most straightforward designs. It uses a perforated drum in which heated air is drawn in from the outside and expelled using a suction shoe at the bottom.

b. Hi-coater operates similarly to Accela-cota. In this system, the drying air is directed from the outside and then passes through the tablet bed to be exhausted via the perforations.

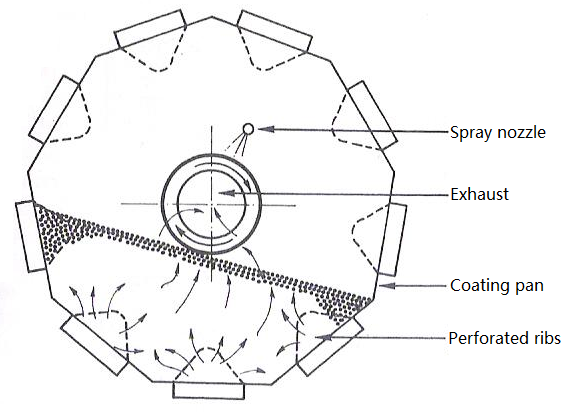

c. Driacoater features hollow perforated ribs positioned on the inner periphery of the drum to deliver heated air for drying tablets. The ribs let heated air in by getting immersed into the tablet bed as the coating pan spins. And then the air flows upwards and leaves the drum.

d. Glatt coater is equipped with a fully perforated drum and multiple high-speed spray nozzles. In this system, heated air is directed inside the drum and passes through the tablet bed to leave via the suction shoe. The glatt coater features maximum spray rates and short processing time of the tablets.

3. Fluidized bed or air suspension system

When it comes to the highly efficient types of tablet coating machines, the fluidized bed, also referred to as the air suspension system, always stays atop the rankings.

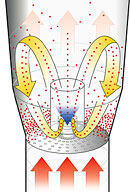

This machine features a vertical cylinder. After tablets are loaded into the machine, high-pressure air is forced upwards to suspend and fluidize the tables. In the meantime, the coating solution is sprayed onto the tablets using spray nozzles. A perfect layer of coating is left behind after the solution evaporates in the air, or the melt cools and solidifies as a result.

Different fluidized beds come with spray nozzles that are mounted in different positions. Depending on how they spray the coating solution, there are typically three patterns of fluidized beds.

a. Top spray is suitable for general coatings and even enteric coating. In this process, heated air enters the machine from the bottom to fluidize the tablets. As its name implies, this fluidized bed is equipped with a spray nozzle at the top. The nozzle sprays the coating solution onto the tablets from the top against the heated airflow. The tablets get dried by flowing upwards in the heated air.

b. Bottom spray is also known as the Wurster process. In this fluidized bed, the spray nozzle is mounted at the bottom, and the spray pattern is concurrent with the heated airflow. This device is fabricated with a Wurster tube and a bottom plate. During the process, the tablets travel upwards through the Wurster tube and fall back down to the bottom plate.

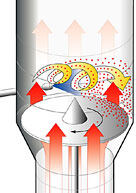

c. Tangential spray is suitable for applying a very thick layer of coating to tablets. It's equipped with a rotor mounted at the bottom. As it rotates, heated air is introduced into the fluidized bed through a gap between the rotor and the wall. The tablets are set to a spiral motion and sprayed with the coating solution by a nozzle arranged tangentially to the rotor.

Final thoughts

As you can see, whether you're a startup or a scale-up of tablet manufacturing, you have many different types of tablet coating machines to choose from. Not all tablet coating machines are equal however, with some types are available for several airflow configurations while some tablet coating machines are capable of coating multiple unit dosage forms.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche